Using a spray module, defined areas on the assembly can be wetted with a flux.

EUTECT Modular System

SF: Spray fluxing

The application is contactless and very precise. The flux point diameters can be defined depending on the application. The spray fluxer draws the flux from a connected pressure vessel.

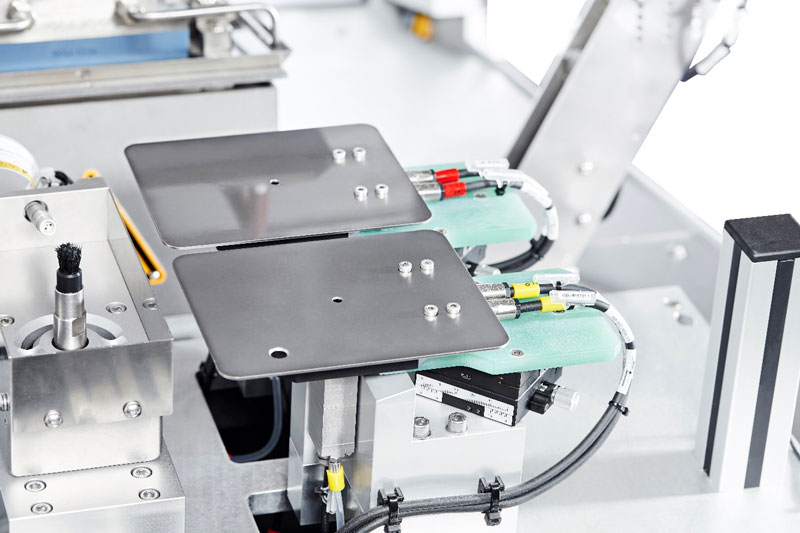

BF2: Brush fluxing

Brush fluxing enables very precise preparation of two process areas with one area-covering application.

Two application brushes are used simultaneously. Several flux points can be wetted reproducibly and with optimised cycle times without spraying. This method is used for flux point diameters of 1.5 mm or more.

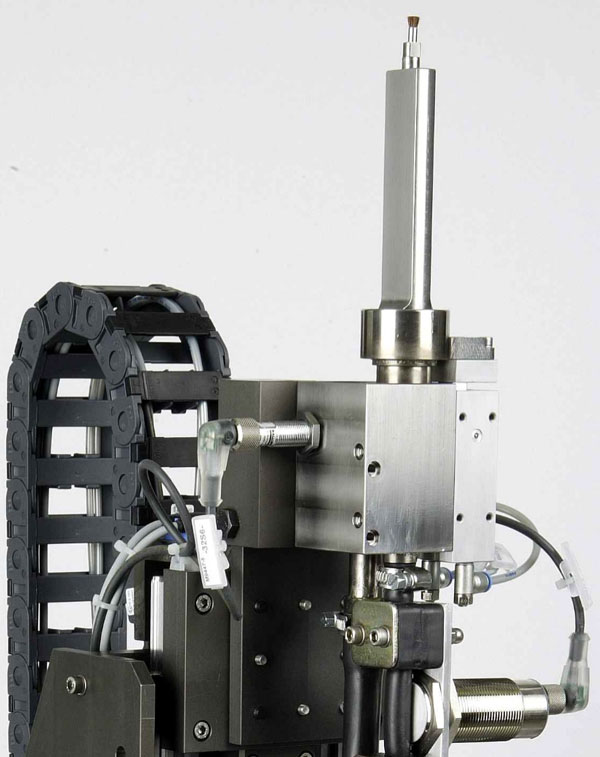

BF1: Brush fluxing

Brush fluxing allows a very precise preparation of the process area with a full-coverage application.

Several flux points can be wetted reproducibly and with optimised cycle times without splashing. This process is used for flux point diameters of 1.5 mm and above.

IF: Inject fluxing

The contactless, cycle-time-optimised flux application by means of an inject flux head can be carried out from all directions and is independent of the position or installation situation.

The amount can be determined by the duration of fluxing.

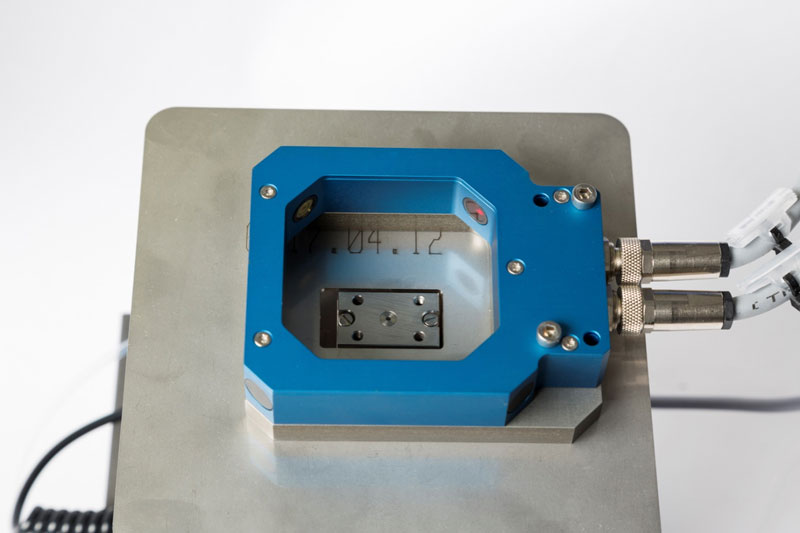

LDF: lift/dip fluxing

In lift-dip fluxing, the component to be wetted is immersed in the flux.

All flux types can be applied with this application method using lift-dip fluxing. A reproducible wetting level can also be achieved for fluxes that have a high solids content.