In mini-wave processes, the free-flowing solder wave is created by pumping up the molten solder from a heated storage tank.

EUTECT Modular System

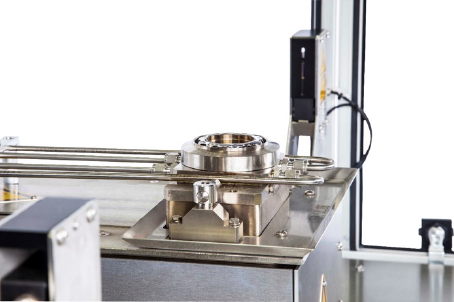

IW1: Mini wave soldering module

Unused solder melt flows back into the tank, creating a closed solder circulation. The induction solder pump system based on the electromagnetic drive principle works without moving parts in the solder. The controlled solder flow with a close-fitting inert gas atmosphere, together with the homogeneous heat transfer, is the basis for the best solder quality, which is free of residues and oxides. The solder wave height is controlled by laser.

The IW1 soldering system can be equipped with all available nozzles from Eutect.

EUTECT SMART soldering automation

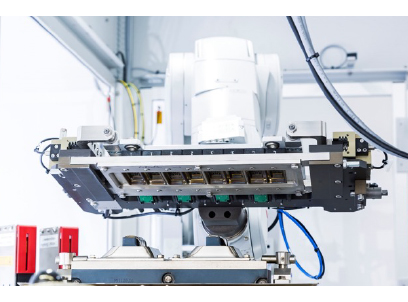

IW1-2: Mini Wave Soldering System

In mini-wave processes, the free-flowing solder wave is created by pumping up the molten solder from a heated storage tank.

Unused solder melt flows back into the tank, creating a closed solder circulation. The induction solder pump system based on the electromagnetic drive principle works without moving parts in the solder. The controlled solder flow with a close-fitting inert gas atmosphere, together with the homogeneous heat transfer, is the basis for the best solder quality, which is free of residues and oxides. The solder wave height is controlled by laser.

The IW1-2 can be equipped with two nozzles from Eutect.

EUTECT SMART soldering automation

HT1: Lift-dip soldering module

The immersion soldering system is a solder bath that enables leaded and lead-free soldering at a temperature of max. 450°C. The solder bath can be used for the soldering of metal parts.

The areas to be soldered are immersed in a molten solder alloy. High-performance thermal jaws keep the liquid solder constant at a defined solder temperature. This can be kept at ±2.5°C by means of solder temperature control. The solder module content is 25 – 30 kg.

The solder bath is equipped with a servo-motorised squeegee, as well as a sensor and pressure-monitored inert gas process control (nitrogen) and an automatic solder bath level control. Specific solder bath covers ensure minimum oxidation and maximum accessibility.

IW1: Point longitudinal wave soldering module

For the point longitudinal shaft, two IW1 modules are used, which are equipped with different nozzles.

Both a spot nozzle for soldering individual pins and a longitudinal nozzle for soldering several pins simultaneously can be used. In mini-wave processes, the free-flowing wave of solder is created by pumping up the molten solder from a heated supply tank. Unused molten solder flows back into the tank, creating a closed solder circulation.

The induction solder pump system based on the electromagnetic drive principle works without moving parts in the solder. The controlled solder flow with a close-fitting inert gas atmosphere, together with the homogeneous heat transfer, is the basis for the best soldering quality, which is free of residues and oxides. The solder wave height is controlled by laser.