From our process modules of the modular soldering technique, the optimal modules with regard to process technology and efficiency are selected for the task and combined to proven stand-alone, rotary transfer or inline production concepts for total solutions.

The EUTECT module toolbox shows, that with individual modules or free combinations a lean, individual solution of proven modules can often be achieved for the task of a customer product.

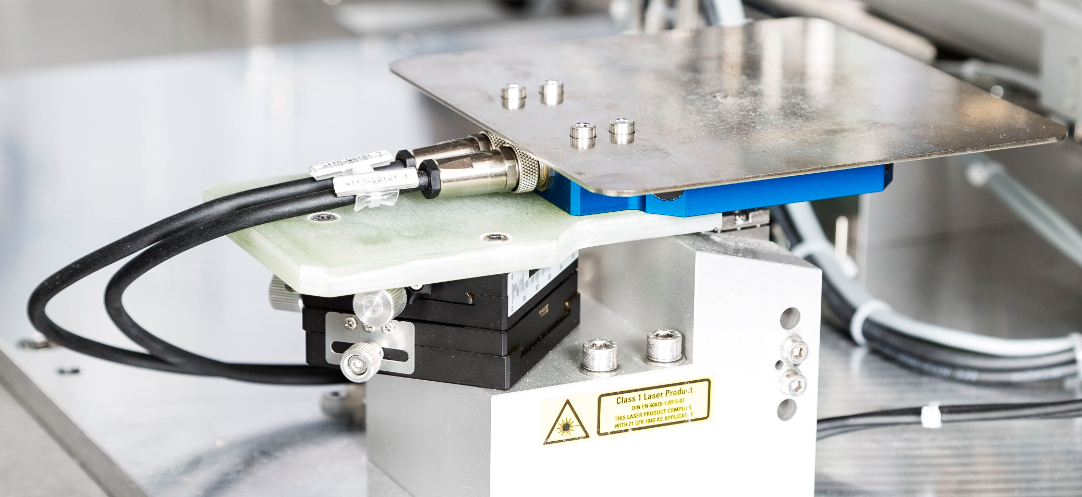

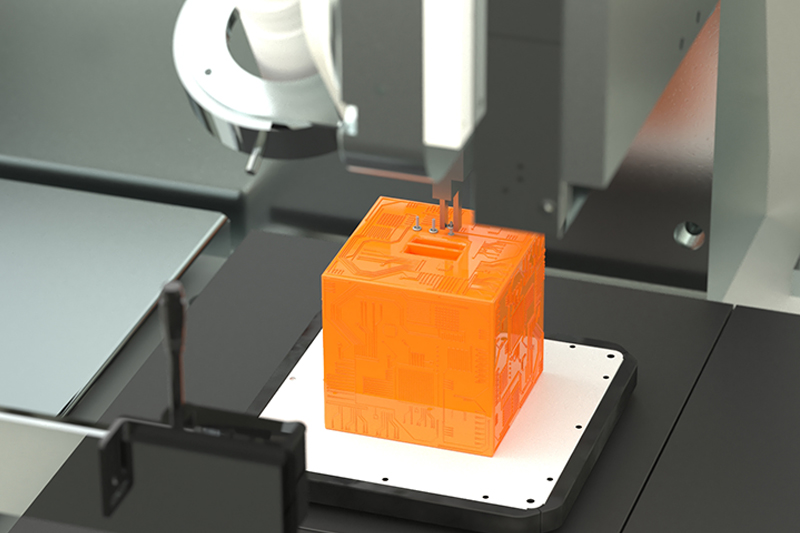

SRS – Sustained Ring Soldering

The Sustained Ring Soldering module produces solder rings from common solder wires, which enable a new cycle time-optimised, highly accurate and economically sustainable assembly soldering.Using the newly developed SRS module, pre-assembled solder rings can be produced on the fly and placed on and around THT pins. These are then processed by means of laser, piston or induction soldering processes, as well as by means of IR emitters or hot air. The SRS module is a fully automatic ring production device that is used to produce specific solder rings from customer and product-specific solder wires, with or without flux core. Depending on the tool used, different solder wires with defined ring diameters can be produced. The automatically reproducible solder rings can be positioned manually, with the help of special tweezers and magazine dispensers, as well as automatically by means of a special, highly dynamic pick & place handling system on the solder joints to be processed or over the plated-through pins.

Solder rings in size comparison

Added customer value

- Highly accurate soldering processes due to reproducible solder quantities

- Sustainable, as almost 100% of the solder wire is processed

- No inert gas atmosphere (nitrogen) required

- Low space requirement compact design, freely integrable and modularly expandable

- Cycle time optimised (I) due to the elimination of pre-heating times and immediate availability

- Cycle time optimised (II) by decoupling the assembly and soldering process

- ➞ Cost-reducing because energy-saving, minimum service effort and cycle time-optimised

EUTECT SRS process steps

Wire feeds

Besides non-regulated wire feeders for diverse wire thicknesses, EUTECT also offers the only force-controlled wire feeder in the world: the Sensitive Wire Feeder (SWF).

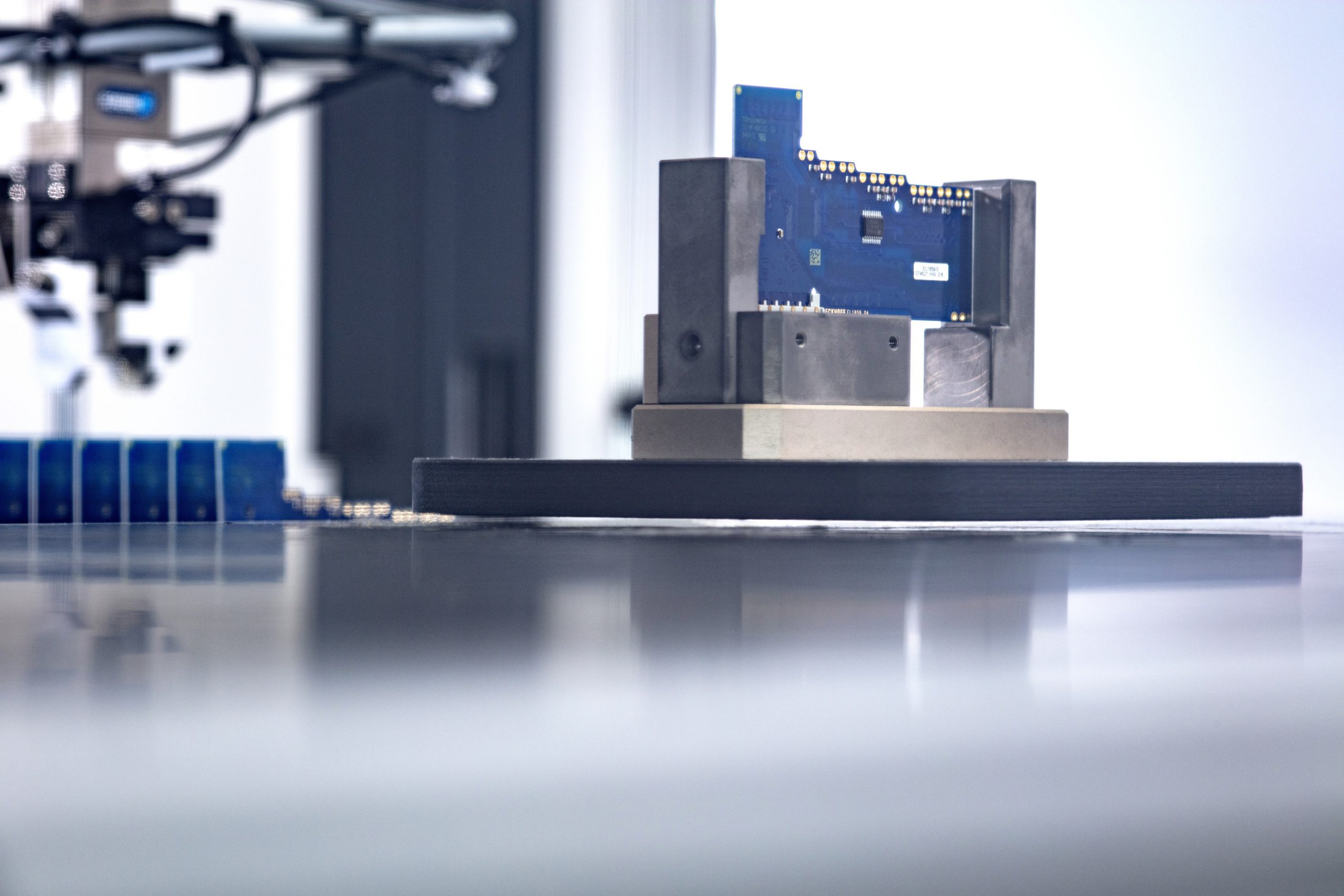

Workpiece carrier & Mask technology

For transport and protection of assemblies within the plant, workpiece carriers (WC) and soldering masks are used. These are developed individually for the assembly to be processed.

Fluxing

- Freely integrable and expandable flux modules

- Highly precise inject fluxing

- Splash-free brush fluxing

- Area efficient spray fluxing

- Cycle-time optimised lift/dip fluxing

- Lasting flux treatment

- Reproducible flux monitoring

- Quantity- and position-monitored inject fluxing

Preheating / Cooling

- Freely integrable and expandable preheating and cooling modules

- Exact temperature processes due to tunnel systems

- Pyrometer-controlled heat input

- Homogeneous heat input due to blower heating

- Highly dynamic heat input due to quartz radiators and IR heaters

- Heat-protection masks for sensitive assembly areas

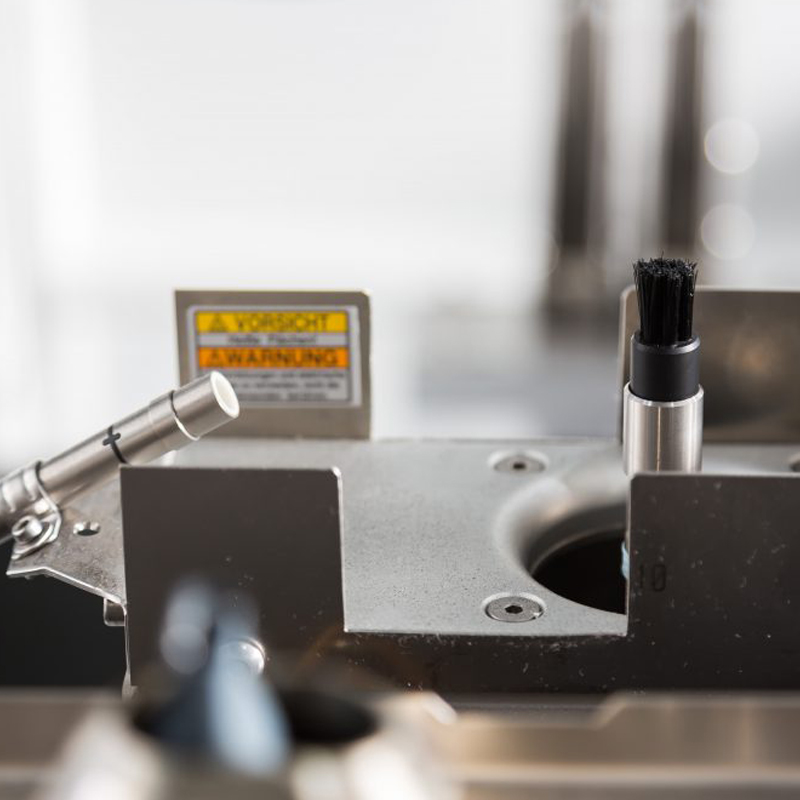

Brushes

- Cleaning of circuit boards

- Low maintenance

- Fast exchange of brush heads

- Durable, stable brush rotation

- Wearing part monitoring

- Integrated extraction

- No static charging

- Speed coordination to circuit board and components

- Defined brush height to circuit board

- Integrated height monitoring

- Round brush

- Fastening with thread

- DC-Motor with fixed speed

- Catch container for dirt particles

- Integrated ionising unit with discharge head

Inspection

- Ensuring maximum quality demands

- Fault-free quality control

- Cost-reduced monitoring

- Constant process speed

- Constant footprint

- Integrated solder joint inspection

- Fully automatic inspection process

- Integration of AOI systems

- Manufacturer-independent

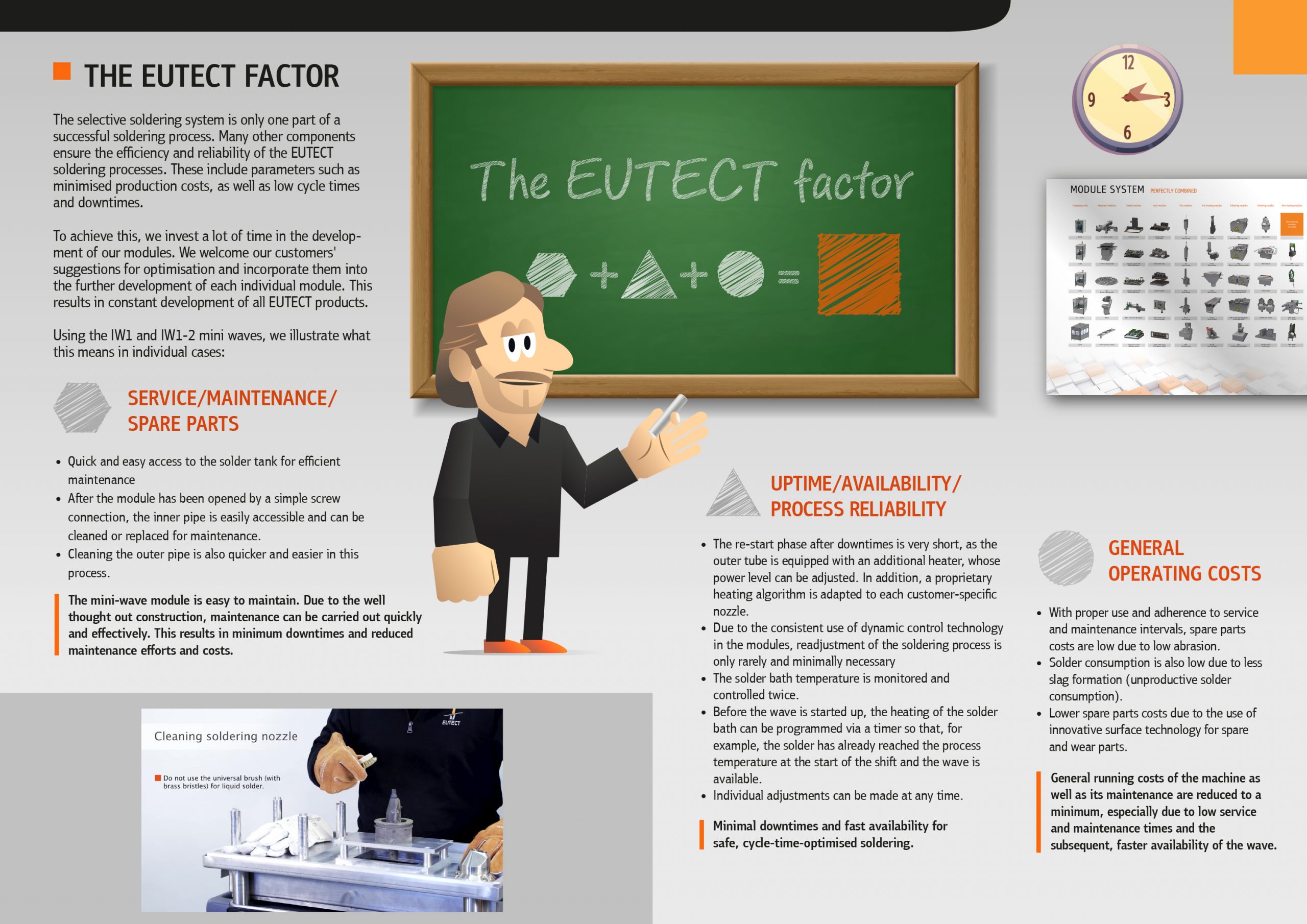

The EUTECT factor

Many pieces of the puzzle make the EUTECT soldering processes efficient and reliable.

This includes parameters such as minimized production costs, as well as low cycle times and downtimes.

To achieve this, we invest a lot of time in the development of our modules. We take our customers’ suggestions for optimization and incorporate them into the further development of each individual module. This results in constant further development of all EUTECT products.

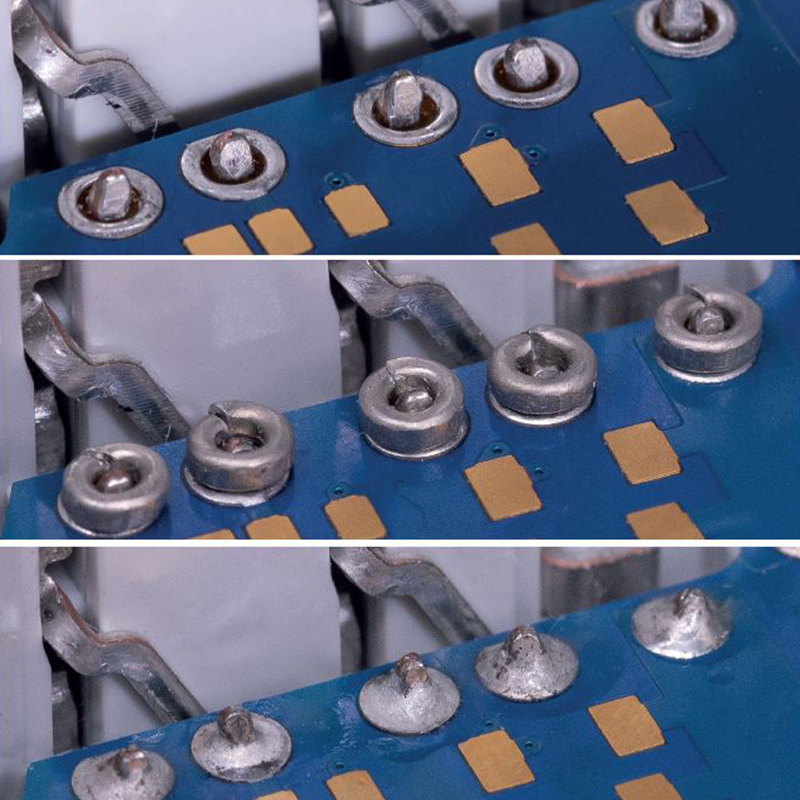

Using the IW1 and IW1-2 mini-waves, we illustrate what this means in individual cases.

The EUTECT factor

Downloads

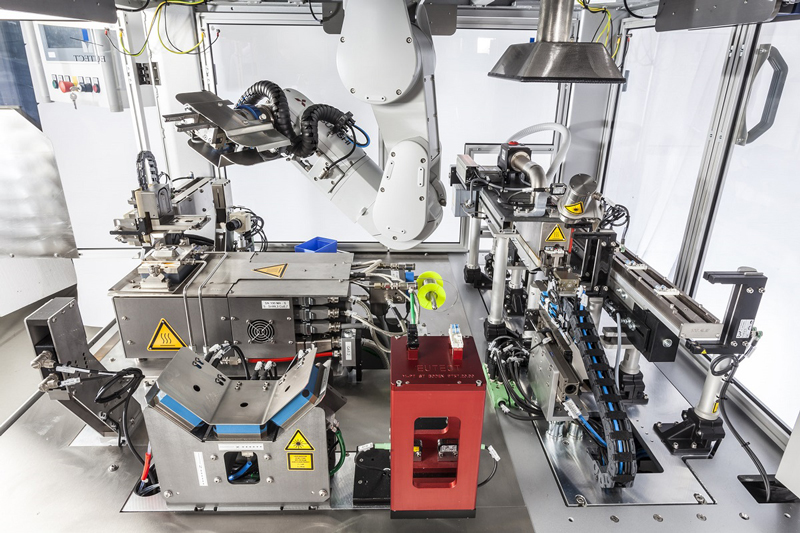

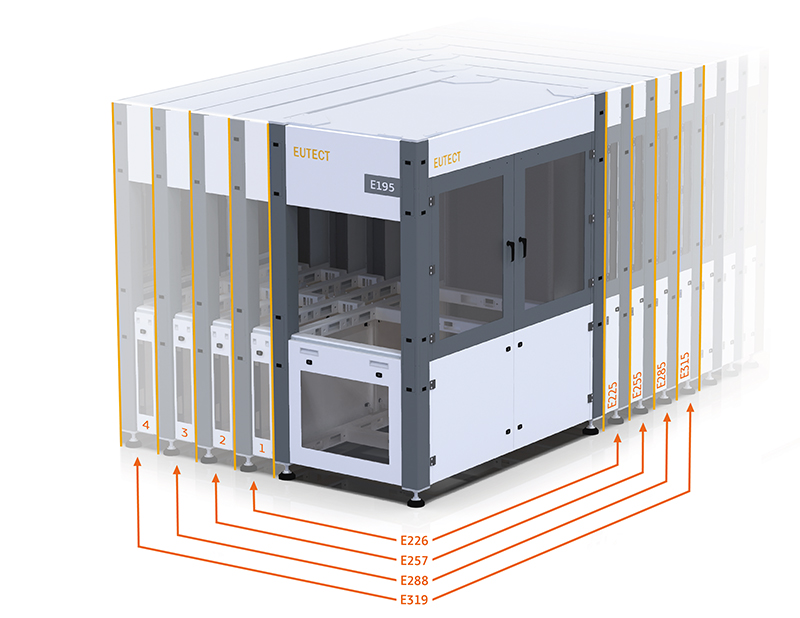

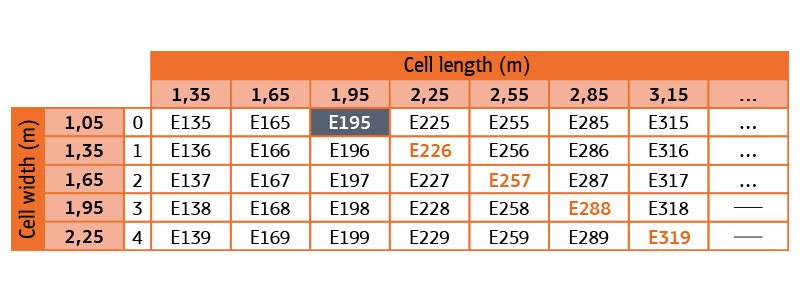

E-CELLS, EUTECT Automation cells

Our scalable E-CELLS stand for efficient use of space as well as modularity with precision and sustainability.

With a grid dimension of 300mm in width and length, each automation cell can be individually adapted to a wide range of tasks in terms of size, optionally also in terms of height. To implement our EUTECT cradle-to-cradle principle even more sustainably, we have reduced the number of control cabinets and replaced them with centralised and easily exchangeable cabinet solutions. On the one hand, these cabinet solutions support service and maintenance efficiency, and on the other hand, they enable a new, less complex but more clearly structured wiring concept. And in addition to all these sustainable benefits, the rigidity of the automation cells has been increased by over 50%.

Modularity beyond the standard

- Tailor-made flexibility through cell extension in length and width

- Highest rigidity for precise soldering and automation processes

- Central control cabinet for efficient service and maintenance services

- Real sustainability thanks to integrated cradle-to-cradle concept

EUTECT-Kinematics

In the framework of an evaluation, the right kinematics modules are selected for the customer. The assemblies, possible workpiece carriers, cycle times, production volumes and the soldering modules used thereby play a part.

Different combinations of cells, handling- and process modules are possible according to the task. From this variety of combinations, individual solutions beyond the standard can be implemented, that are oriented to the customer requirements in every detail.

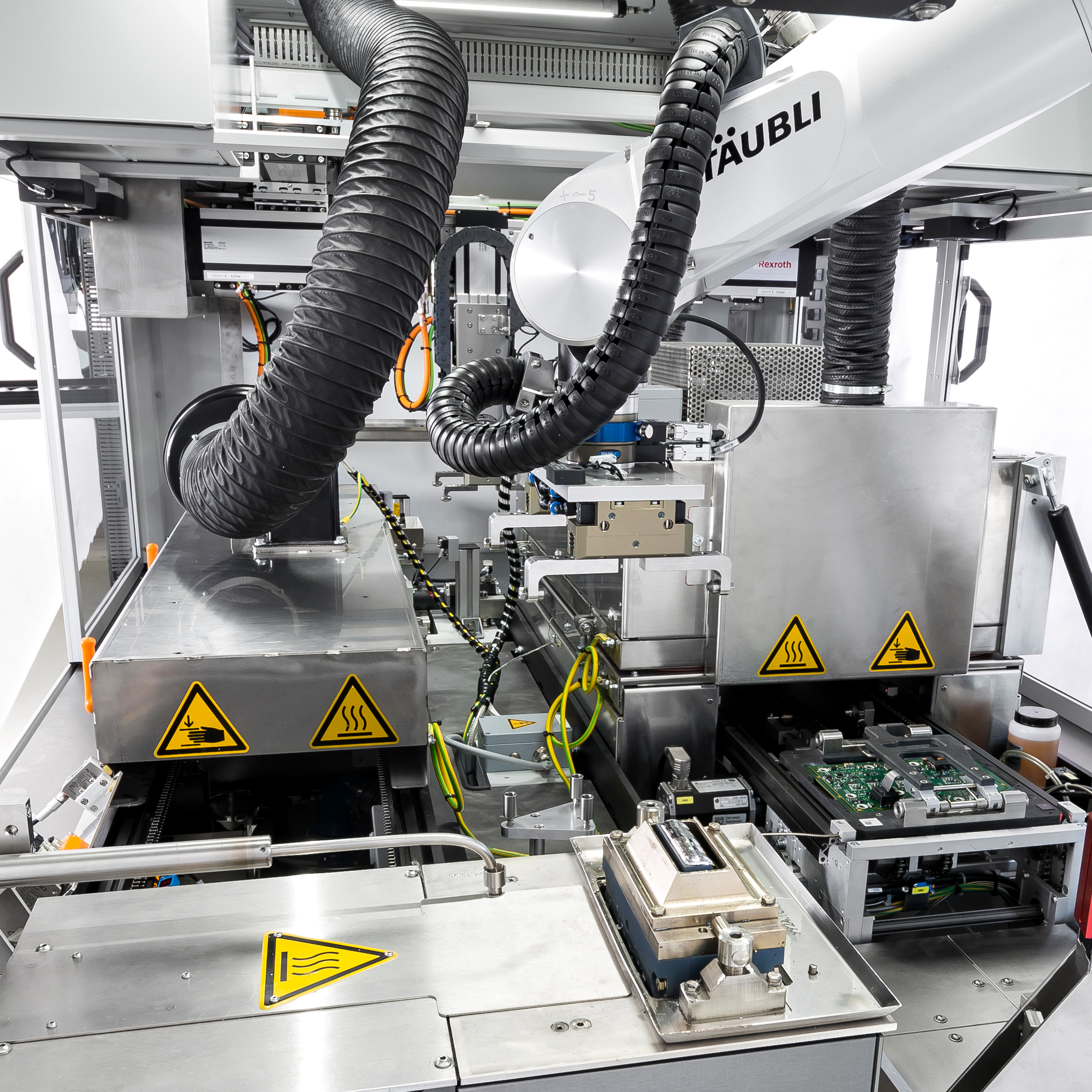

Rotary Indexing Table Automation

- Simultaneous process management and assembly transport

- Increase of the cycle times

- Error minimisation thanks to simple, manual placement

- Process independent

- Individual adaptation to assemblies and workpiece carriers

- Defined work process

Robot Automation

- Space- and material efficiency due to 6-axis robots

- Up to two 6-axis robots in one system

- Versatile process possibilities

- Saving of workpiece carriers and belt systems

- Overhead integration

- Reduced machine footprint

- Low maintenance

- Process independent

- Highly flexible arrangement of process- and test modules in the smallest installation space

- Precise control and easy programming

- Versatile gripper/soldering mask combinations for a high level of flexibility

- Development of own, mountable and product-specific workpiece carriers

- Regulated process

For the transport of the assemblies in our systems, in addition we also offer X-Y-Z-axis modules, X-Y-Z-D-lift modules and Inline belt systems.

Integration of cobots

E-ssembly

With E-ssembly, we are introducing a completely new “line” production concept that is characterised by maximum flexibility, dynamics and sustainability. The newly created possibilities point the way to the future, not only in electronics production and assembly and connection technology, but also in automation as a whole. By means of the E-cell concept, we offer a new basis for generating maximum customer benefit with integrations such as that of the floating 2D product transport system XPlanar from Beckhoff.

E-ssembly can be used for the following applications:

- Palletising

- Loading

- Assembly

- Soldering

- Dispensing

- Testing

- more applications

For more information on the integration of the XPlanar into our system solutions, please visit our information page.

Automation – modular solution concepts

EUTECT – we stand for smart and modular solution concepts. Our in-house developed and unique EUTECT module toolbox has supported this for more than 15 years. Together with the customer we combine the perfect mix of technologies to develop an optimal system design with a strong focus on optimal process- and product quality as well as a high degree of efficiency.

Maximum production capacity is achieved on a minimal production area.

The → EUTECT Module Toolbox stands for individual, economic and lean solutions.

Inline Laser Automation with AOI

EUTECT automation platform Multiple Process Changer (MPC)

The MPC platform is a highly flexible automation solution for a wide range of tasks using a collaborative robot system from Mitsubishi Electric. The standard system is equipped with a light grid protected input and a rotary table for assembly input.

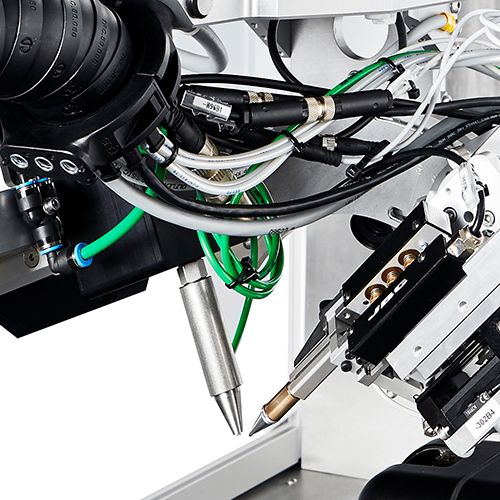

The MPC can be equipped with various tools. In addition to piston soldering heads, dispensers, screw or placement tools and grippers are also being considered for integration into the MPC. Depending on customer requirements, the MPC can be equipped with different tools for different applications. It is also possible to use a wide variety of tools in one work process.

The robot used is a MELFA assista from Mitsubishi Electrics equipped with the latest MR-J5 servo motors in all six axes, which eliminate the need for additional torque sensors.

Not only because of its high rigidity and industrial design, it can set solder dots with the same repeatability as a standard robot, but also because the MELFA assista can also be operated as an industrial robot.

MPC KL

The complete system MPC KL (piston soldering) can be equipped with piston soldering systems from JBC or HAKKO. The soldering iron sits firmly mounted on the arm of the robot, including the wire feed. Robots, control systems and soldering irons are a machine unit. The entire system is completed by the input area, which in the standard version consists of a rotary table for manual component assembly and a safety cell around the soldering process. Furthermore, a soldering tip holder is provided in the process surface itself, with which the fully automatic change of the soldering tips takes place. The same applies to the tip cleaning.

EUTECT Traceability

Soldering process can only be reproduced if individual process parameters and steps are controlled, monitored and documented. EUTECT has developed a large number of these controlled process steps in order to guarantee the traceability of the individual steps within the soldering process at all times.

Below are some examples of controlled EUTECT process solutions:

Temperature, force- and path-contolled thermode soldering

µ – precise penetration depth and °-exact temperature and 0.1N exact force control

Force and path controlled Sensitive Wire Feeder (SWF)

µ – precise path, 1.5N precise force control and 0.05mm precise wire feed

Temperature, force- and path-controlled Laser Knife

µ – precise penetration depth and °-exact temperature and 0.1N exact force control

Preheating, induction and laser modules

Heat input is pyrometer controlled

Flux Modules

Dispensing of flux using flux beam recording for quantity and position control (flux start query)

Brush module

Height-regulated brush monitoring for early wear detection

IW 1 & 2 mini wave module

Height controlled mini waves

Nitrogen soldering

Monitored and regulated nitrogen supply

Monitored and regulated nitrogen supply

Prevents overheating of the solder bath and thus defects on heaters and integrated electronics.

Barcode, RFID and specific reading and writing devices

Standard machine equipment

Suction monitoring by means of flow sensor technology

Flow is measured and the system is only started when the suction is functioning

Application of flux

Checking the flux application by using flux density control (two chamber system)