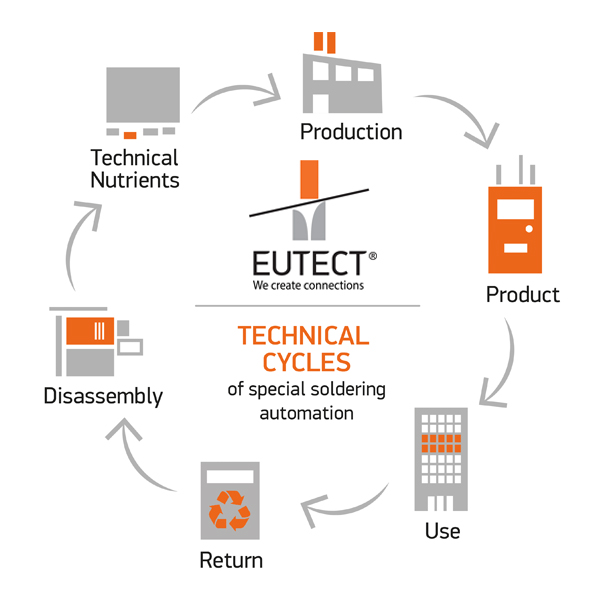

In every unit delivered by Eutect, not only labour time but also material values have been invested, which can be used for new projects. This can be, for example, the production cell, kinematic solutions but also soldering modules such as soldering nozzles, wire feeders or thermodes. If these parts are still operating, they can also be reused and can be integrated into other machine concepts if the sustainability and cradle-to-cradle idea is applied. This approach is based on a continuous and consistent recycling management. After a general overhaul, the cell can be rewired, equipped with new modules and an updated control cabinet that is adapted to the new processes and thus made fit for new tasks. The wiring harnesses can no longer be used, but the previously integrated soldering modules, robots or other kinematic systems can be used in other projects after a test and overhaul. Some of the newly assembled machines are also returned to the production cycle as rental machines. In addition to entire machines, we also overhaul individual modules. These are also tested thoroughly. After the revision, the exchange of wear parts and an extensive function test, the modules are used for new projects or are first put into stock in order to be able to react quicker to inquiries.