Vehicles are equipped with more and more functions and intelligent electrical assistants. On EUTECT’s machines a variety of systems are soldered for the most diverse manufacturers and vehicles, such as for example transmission electronics, components for power-assisted steering and electric drives, parking assistants, distance alert systems, key systems, control elements in the cockpit, headlamps etc.

Industrial automation

The industrial automation systems of today range from the integration of highly specialised processes and their control units through to fully networked Industry 4.0. The most diverse products, such as sensors, electric microdrives, generator parts, conveyor systems etc. are soldered on EUTECT’s machines for today’s tasks and the scopes of application of tomorrow.

Medical technology

In today’s hospitals, medical laboratories and doctors’ surgeries, medical technology and the electronic systems thereby used play an increasingly important role. A fault-free functioning of analysis systems, cardiac pacemakers, operation-accompanying systems or simple electronic clinical thermometers is ensured through stable and reliable solder connections by EUTECT.

White goods

Our daily housekeeping is no longer conceivable without washing machines, tumble dryers and automatic dishwashers. They simplify our life appreciably, and once they stop working we very quickly realise how much we have grown accustomed to this comfort. Drives, controllers and other systems enable this everyday comfort and many of these necessary technologies are manufactured on EUTECT systems. A wide variety of manufacturers of so-called white goods decided in favour of EUTECT, in order to be able to manufacture their products reliably and efficiently.

Consumer goods

Our daily life is no longer conceivable without electronics. Electronics accompany us in all situations, they are a matter of course that we hardly notice, becoming smaller and smaller with increasing multifunctionality. The costs for these high-performance electronics often remain manageable for the end consumers. This can only be achieved when electronics can be manufactured under cost-effective conditions. As on the systems from EUTECT, which enable an efficient, process-reliable and cost-optimised assembly soldering.

Aerospace

Rapid travel, fast flow of goods and communication spanning the globe are part of the social and economic globalisation. Among other things, aircraft and satellite technology enable this progress. The reliability of such technologies thereby plays a great part. Solder joints are under particular scrutiny, especially at high acceleration, as they must withstand the force occurring. This can only be achieved with a highly precise soldering process, as on the systems from EUTECT, where a wide variety of components are manufactured for these applications in the aerospace sector.

Applications of tommorow

One thing is certain: electronic systems will in future be an increasingly important element of our life.

From autonomous mobility, Green Energy, Industry 4.0 through to increasingly versatile communication possibilities, reliable solder connections will be an important factor for the implementation. With its know-how, experience and problem-solving competence beyond the standard, EUTECT will continue to successfully contribute towards this.

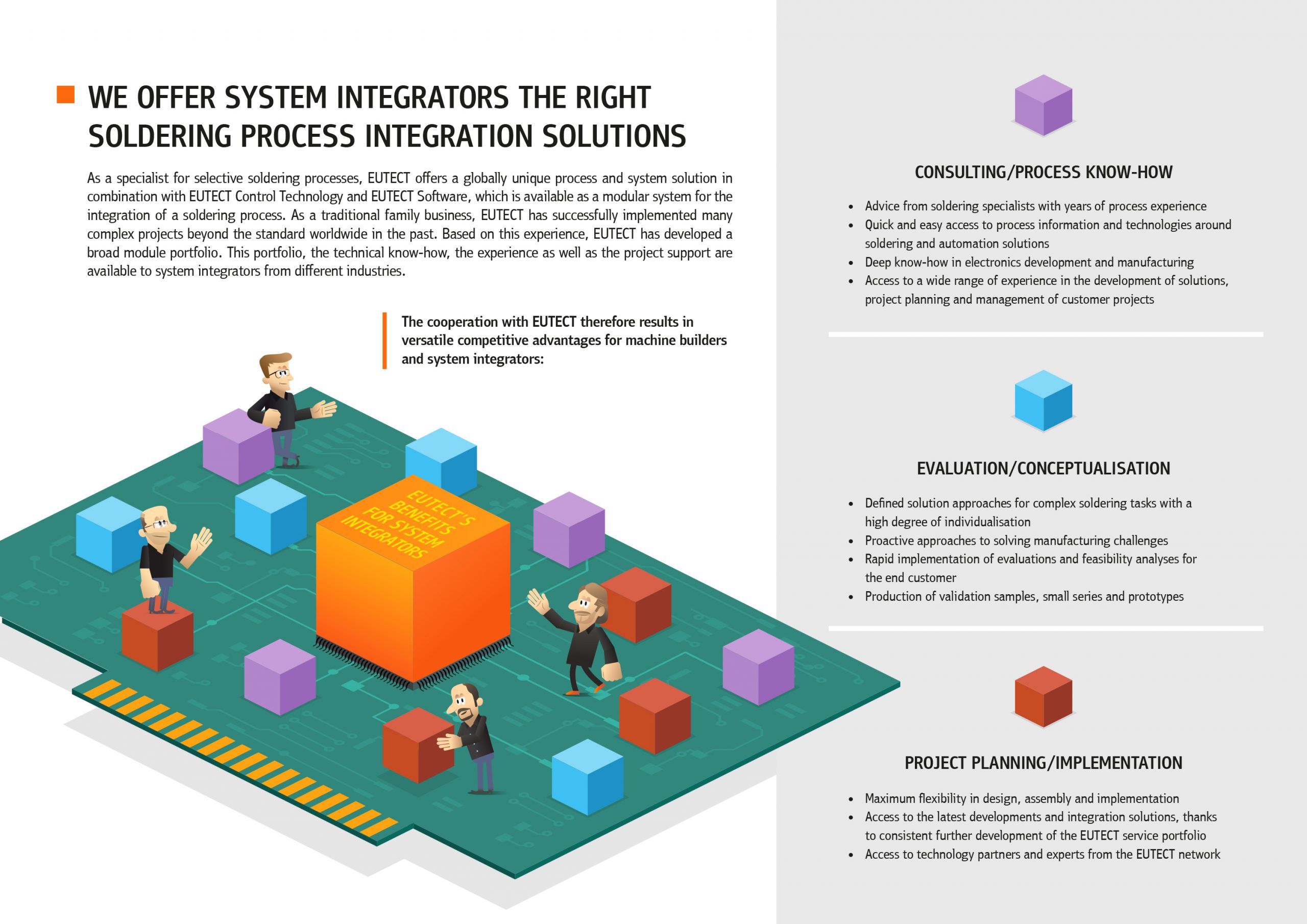

System integration

We offer system integrators the right soldering process integration solutions.

As a specialist for selective soldering processes, EUTECT offers a globally unique process and system solution in combination with EUTECT Control Technology and EUTECT Software, which is available as a modular system for the integration of a soldering process.

EUTECT SMART soldering automation

EUTECT SMART soldering automation

Since the 1990s, the smart and scalable cell concept of EUTECT is making customers happy. Since that time a lot has been developed further, but the minimal footprint and maximal performance has not changed. The application video for the EUTECT SMART soldering automations shows the potential of the cells from EUTECT.

EUTECT Laser soldering

EUTECT Laser Soldering

Laser soldering enables a fast and contactless energy input. Solder wires, solder pastes, preforms and other connecting materials can be processed. Thanks to the use of different wire feeders, customer-specific solutions can be created.

EUTECT IW1 S151 EMS

The IW1 S151 EMS offers high flexibility. Thanks to the automatic product visualisation and the resulting programming of the original product image, almost any product geometry can be approached and soldered using the four axes.

EUTECT Robot Automation

EUTECT Robot Automation

One of EUTECT’s hobbyhorses is the integration of complex robot solutions. But also their little brothers, the Cobots, have found their way into EUTECT production cells. You can find an example here.

The integration of a robot enables the use of a wide variety of processes in a production cell. In some cases up to 5 processes, depending on the cell size, can be controlled with the overhead hanging robot. The assemblies are transported in workpiece carriers, masks or frames. In the three videos we present our skills in this area in detail.

EUTECT Robot Automation

- Space and material efficiency due to 6-axis robot

- up to two 6-axis robots in a single system

- solder mask technology integrated in grippers

- Soldering frame fixture & product specific grippers

- Savings in workpiece carriers and belt systems

EUTECT thermode soldering

EUTECT thermode soldering

The thermode soldering process is used to process flexible foils, cable strands and ribbon cables as well as specific SMD components. One of the largest thermode soldering machines to date is the TL S270, in which five individual processes are integrated in line, including complete process monitoring. The system consists of various individual steps of solder paste application using a dispenser and thermode soldering.