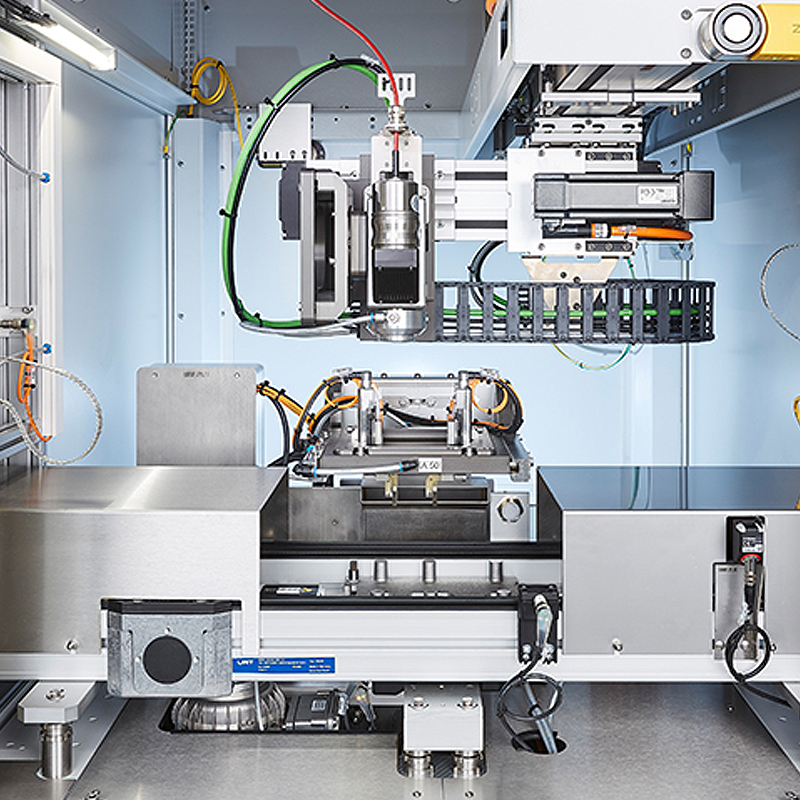

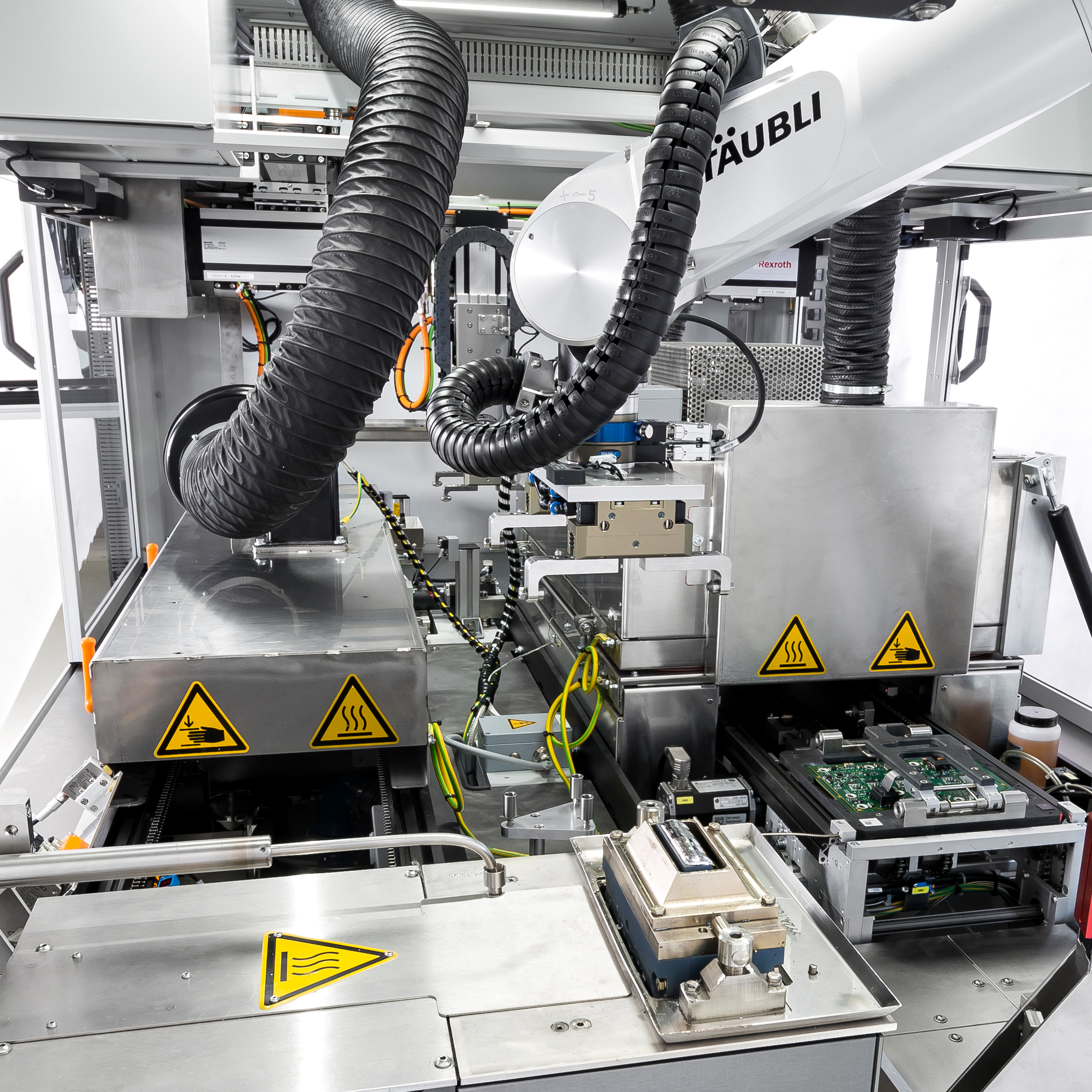

From our process modules of the modular soldering technique, the optimal modules with regard to process technology and efficiency are selected for the task and combined to proven stand-alone, rotary transfer or inline production concepts for total solutions.

The EUTECT module toolbox shows, that with individual modules or free combinations a lean, individual solution of proven modules can often be achieved for the task of a customer product.

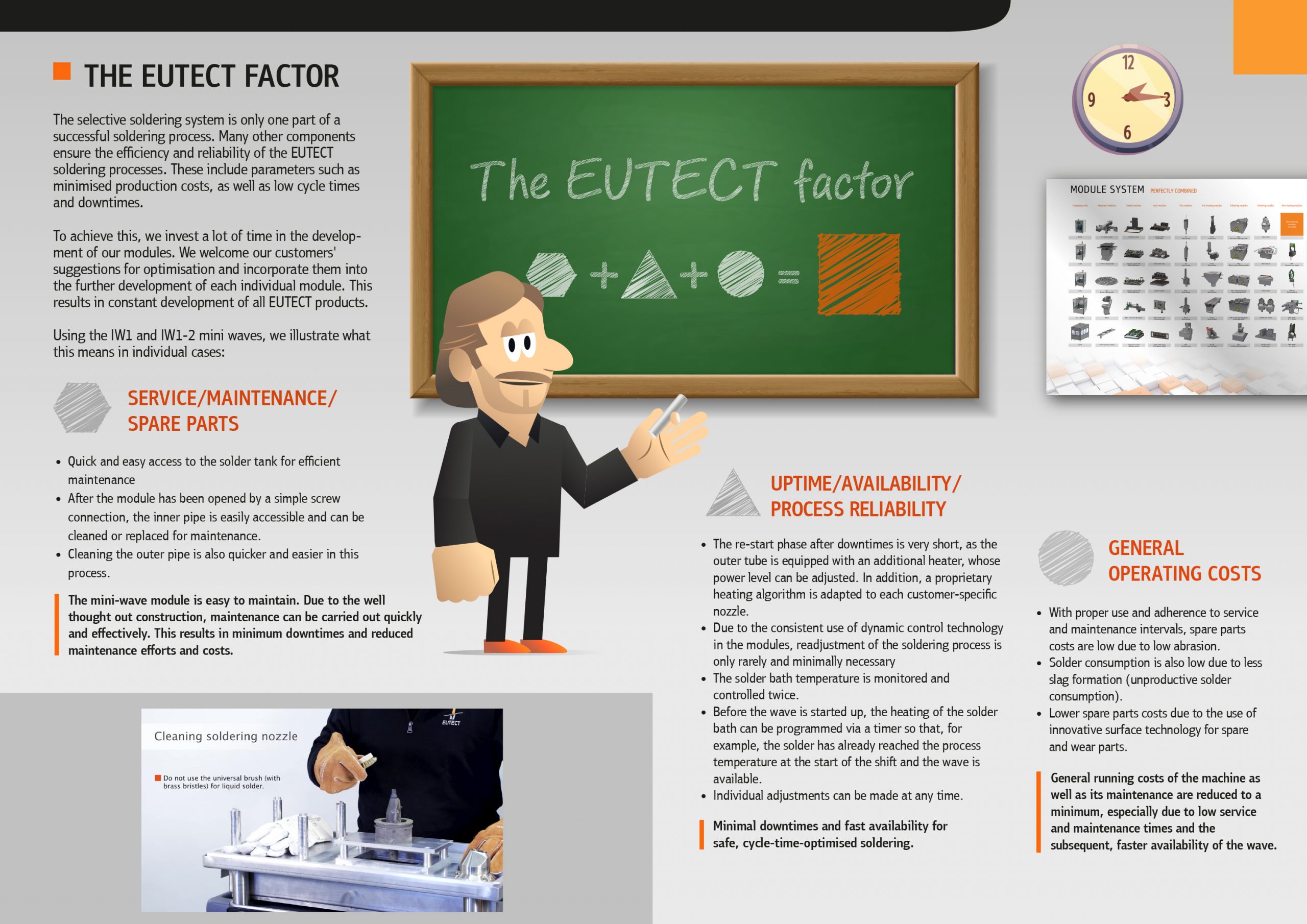

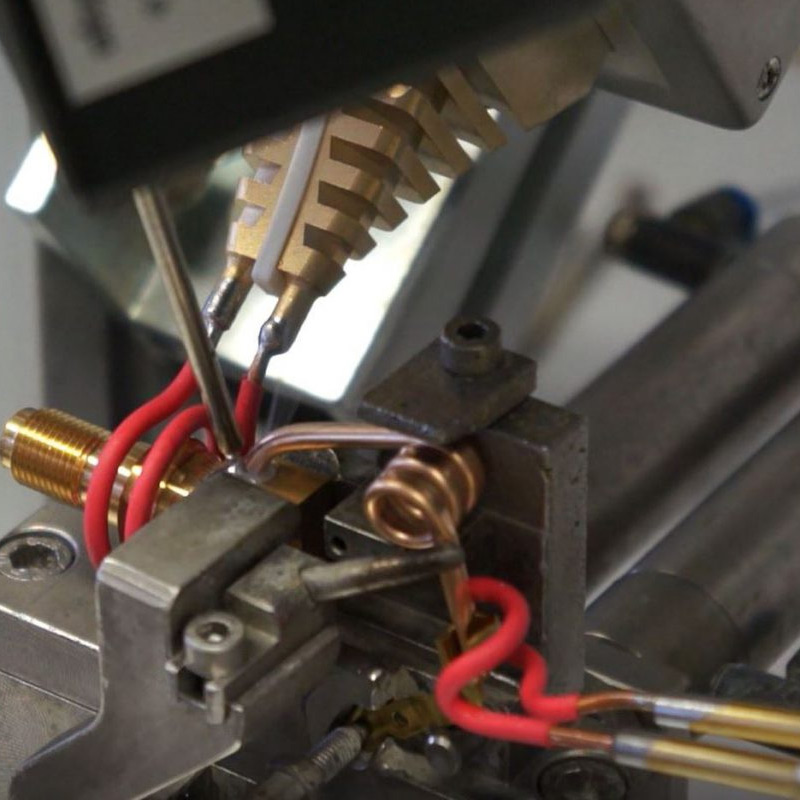

Miniwave soldering

- Maximum solder joint quality

- Minimal scrap

- Minimal solder consumption

- Maximum system autonomy

- High process reliability

- Minimum footprint

- 100% traceability

- Maximum connection quality

- Maximum service life

- Minimal service work

- Nitrogen environment (optional)

- Reproducible solder flow

- Freely definable solder flow

- Constant process stability

- Induction pump

- Nitrogen supply

- Individual soldering nozzles

- Maintenance-reducing surface coatings

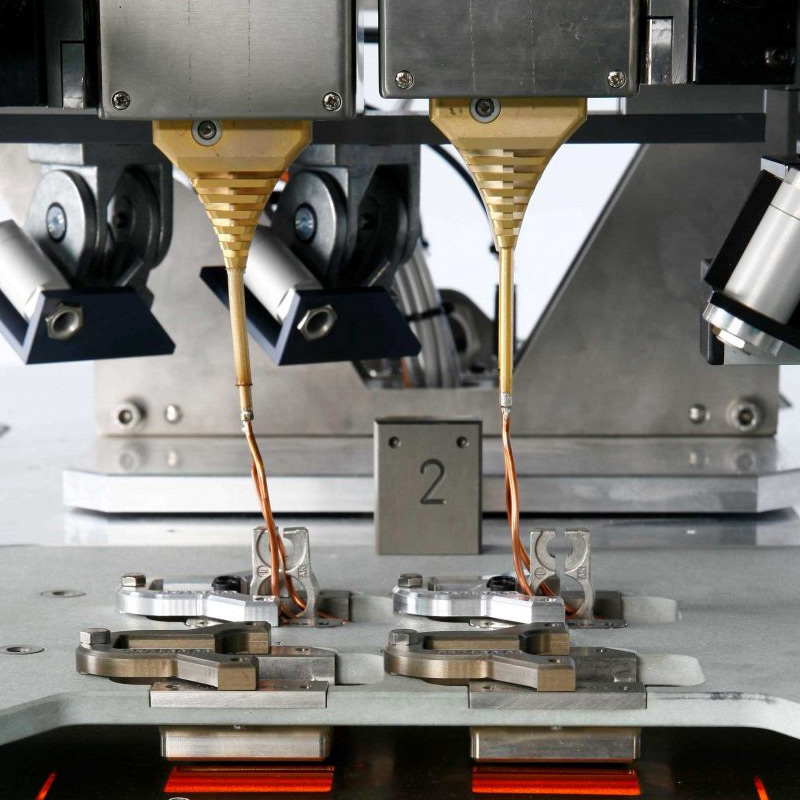

Noozle technology

- Individual nozzle geometries

- Long service life

- Optimal cycle time

- Maximum solder joint quality

- Flexible nozzle technique

- Pressure mask technique

- Flexible nitrogen mask technique

- Low maintenance

- Integrated nitrogen supply

- Definable solder reflux

- Constant, laminar solder flow

- Minimised risk of solder beads

- Maximum solder nozzle geometry (90 mm height, 140 mm width)

Induction pump

- 80% less requirement for replacement parts

- 50% less service- and maintenance work

- Minimal installation space

- Long service life

- Magnetic induction pump

- Soldering speed up to 8 mm/sec

- No rotating parts in solder

- High-temperature soldering up to 450°C soldering temperature

- Flow

- 400 and 800 Watt output

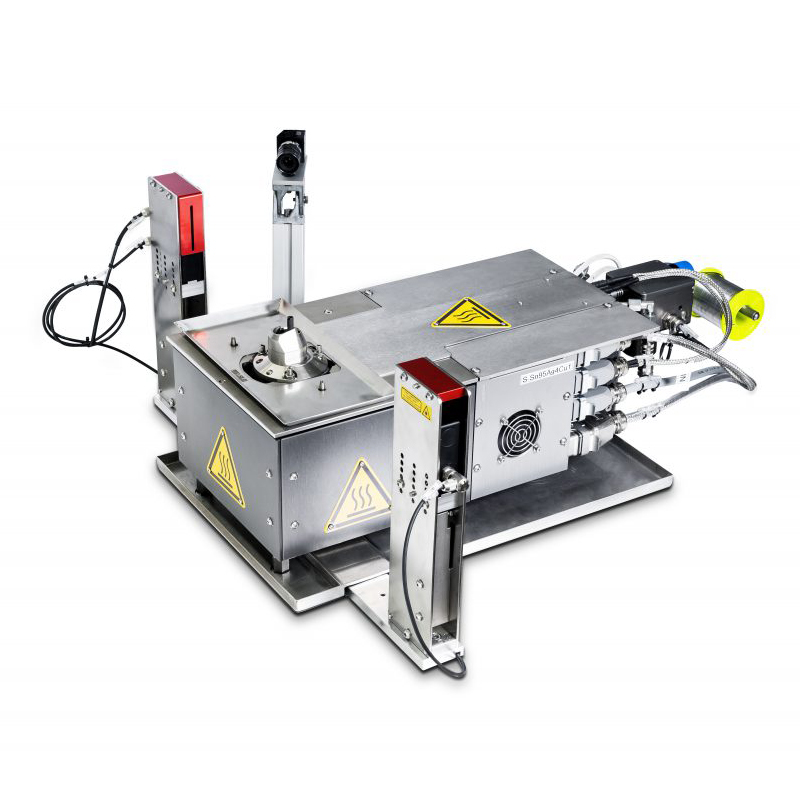

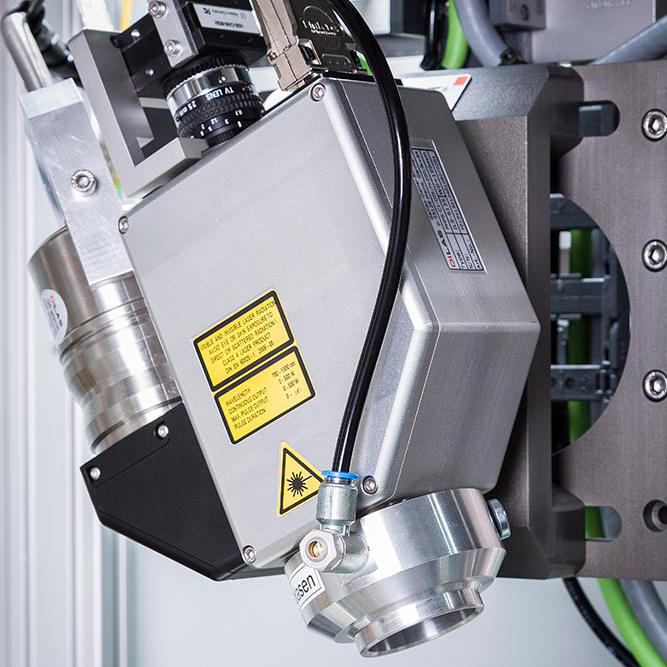

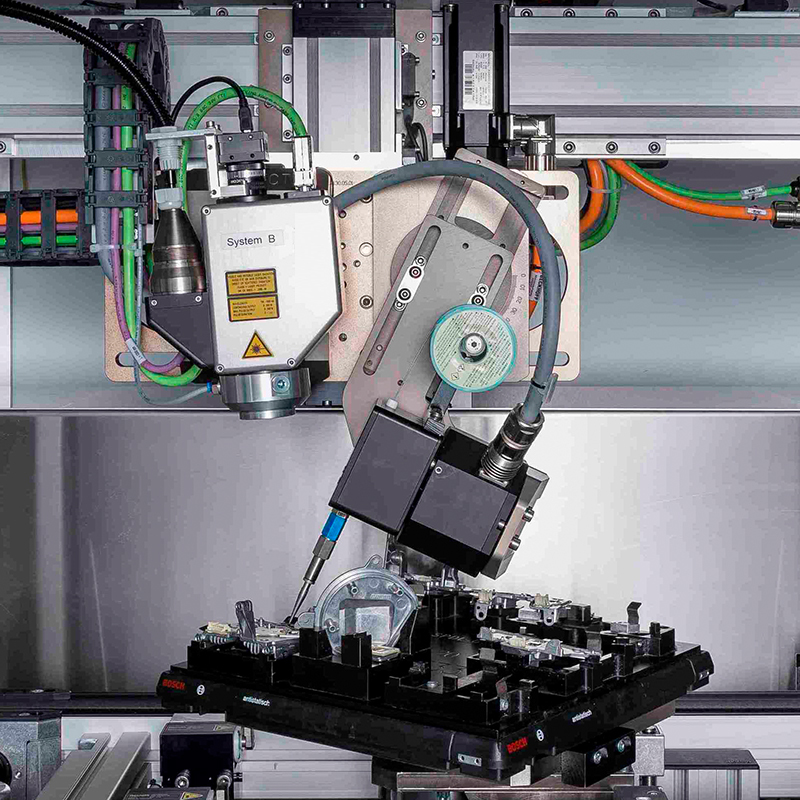

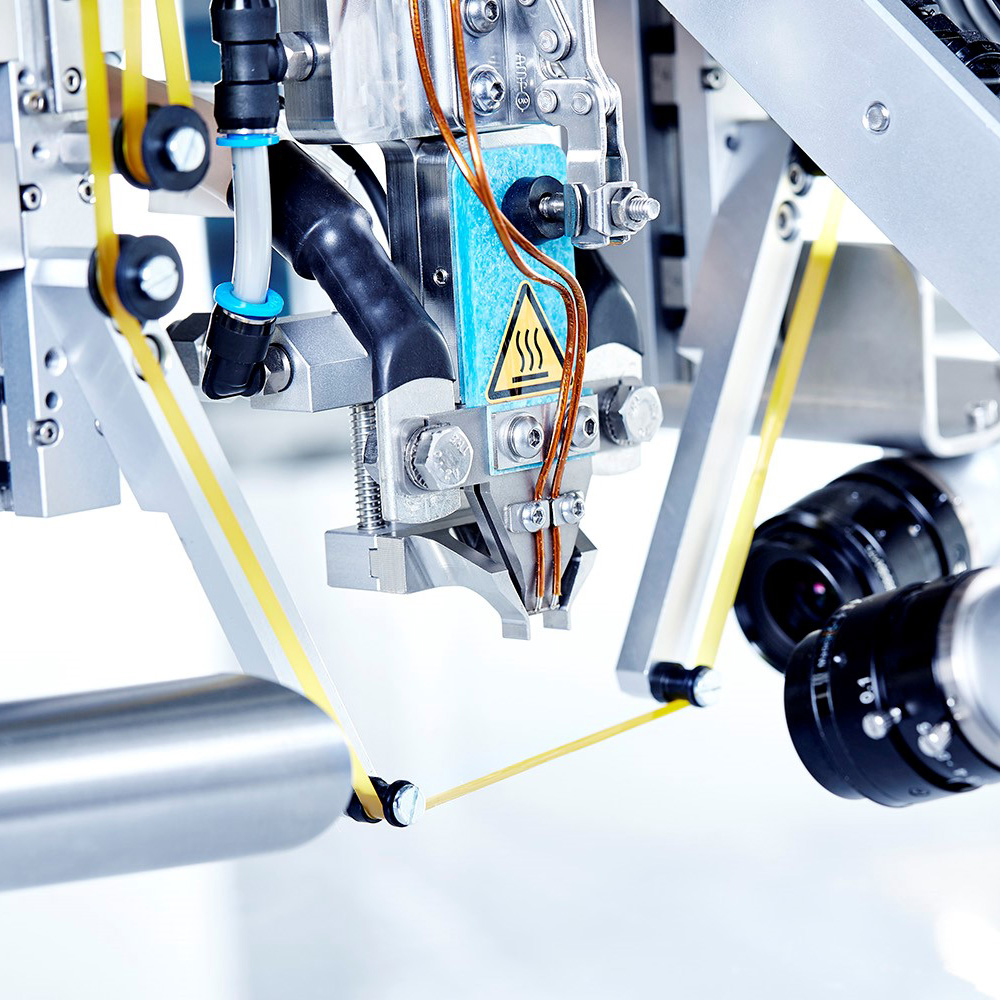

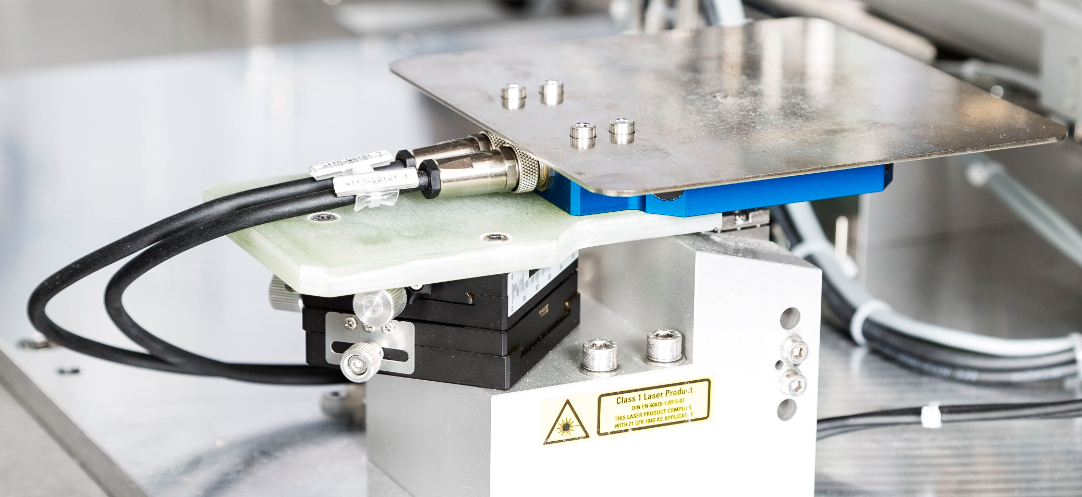

Laser soldering

- High level of flexibility

- Short setup times

- Maximum energy efficiency

- Minimal solder consumption

- Minimal requirement for replacement parts

- Low maintenance work

- Minimum footprint

- 100% traceability

- Maximum service life

- Minimal service work

- Freely definable energy input

- Non-contact energy input

- Immediate system- and process availability

- 25 to 1500 Watt diode laser

- Regulated wire feed (SWF)

- Integrated High-Speed pyrometer control

- Eutect Recording Inspection Camera (ERICa)

- Air Knife

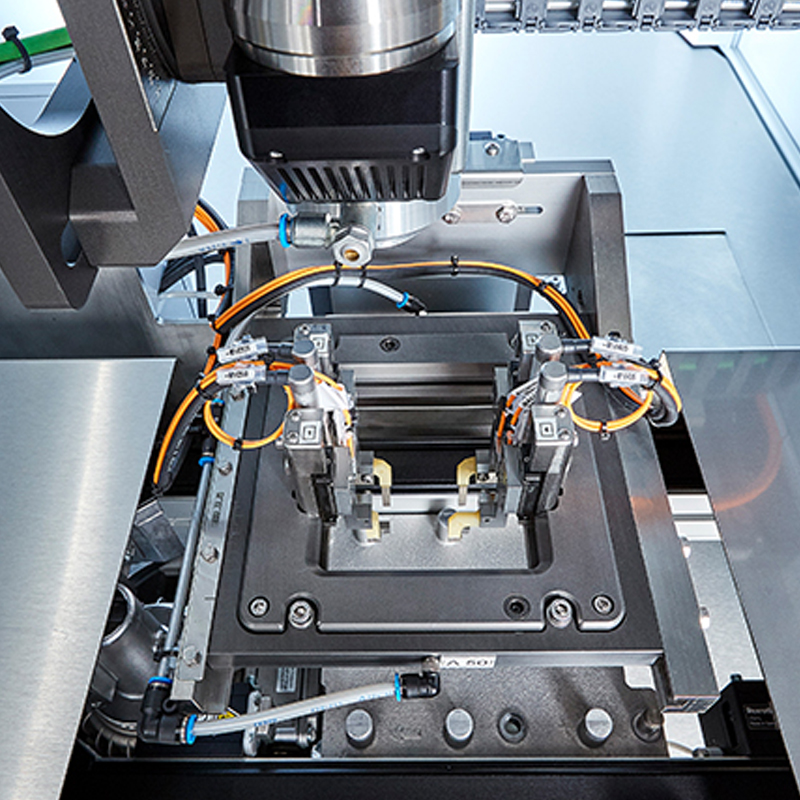

Induction soldering

- Energy efficient

- Minimal solder consumption

- Low maintenance work

- Minimum footprint

- 100% traceability

- Maximum service life

- Freely definable energy input

- Non-contact energy input

- Immediate system- and process availability

- Fast temperature input

- Regulated wire feed (SWF)

- Integrated High-Speed pyrometer control

- Eutect Recording Inspection Camera (ERICa)

- High-frequency systems up to over 25 kW

Piston soldering

- Short setup times

- Minimum footprint

- 100% traceability (optional)

- Product-specific soldering tips

- Immediate system- and process availability

- Freely-definable soldering iron feed

- Automatic soldering tip change

- Regulated wire feed (SWF)

- Integrated nitrogen supply (optional)

- Integrated extraction

- Attachment of soldering irons of diverse manufacturers

- Eutect Recording Inspection Camera (ERICa) (optional)

Thermode soldering

- High energy efficiency

- Short setup times

- Cycle time optimisation of up to 70%

- Minimal solder consumption

- Low maintenance work

- Minimum footprint

- 100% traceability

- Specific thermode geometries

- µ-precise penetration

- Penetration control 1µm

- Contact force is indicated in steps of 0.5 N

- Temperature-Force-Distance Control

- Contact pressure of 1-60 N

- Fast heat input

- Fast, integrated cooling

- Redundant temperature measurement

- Maximum service life

- Freely definable energy input

- Immediate system- and process availability

- Thermode supply through intelligent linear axes

- Up to 600A power

- Leading and lagging hold-down device

- Minimal installation space

- Integrated Kapton roller

Laser Knife

- Dynamic/cycle-time optimised soldering process

- Maximum process stability

- Maximum energy- and resource efficiency

- Can be used independently

- High process speed

- Short setup times

- Minimal solder consumption

- Minimal service- and maintenance work

- Low requirement for replacement- and wearing parts

- Minimum footprint

- 100% traceability

- Maximum process reliability

- Specific laser knife geometries

- µ-precise penetration

- Penetration control/-regulation 1µm

- Contact force can be regulated with 0.5 N

- Temperature-Force-Distance Control

- Fast heat input

- Fast, integrated cooling

- Redundant temperature measurement

- Maximum service life

- Freely definable energy input

- Immediate system- and process availability

- Temperature-controlled laser

- Integrated pyrometer control

- Eutect Recording Inspection Camera (ERICa) (optional)

- Galvo optics

- X-fold knives

- Leading and lagging hold-down device

- Minimal installation space

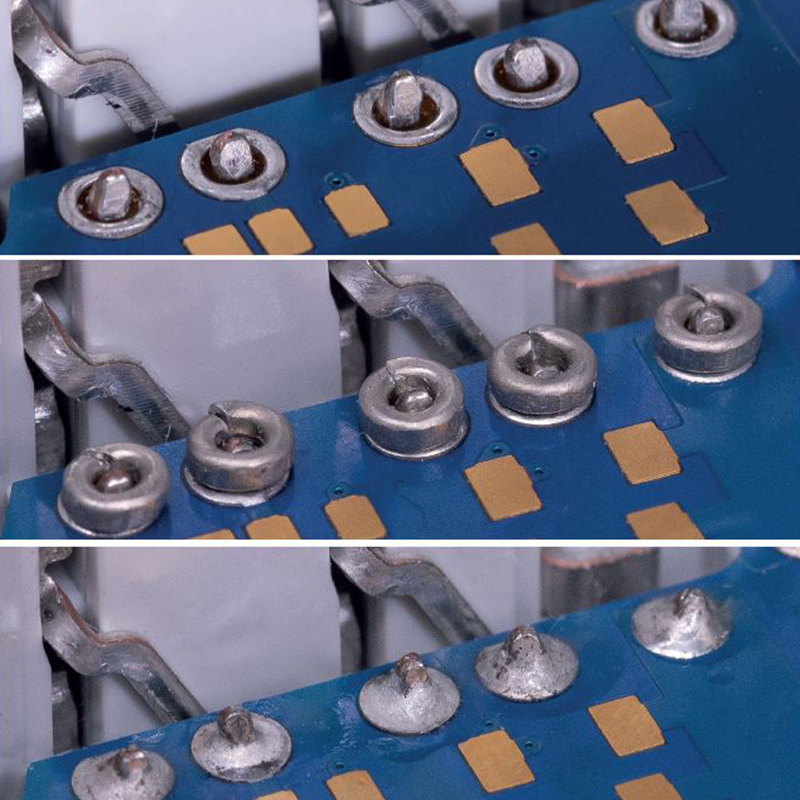

SRS – Sustained Ring Soldering

The Sustained Ring Soldering module produces solder rings from common solder wires, which enable a new cycle time-optimised, highly accurate and economically sustainable assembly soldering.Using the newly developed SRS module, pre-assembled solder rings can be produced on the fly and placed on and around THT pins. These are then processed by means of laser, piston or induction soldering processes, as well as by means of IR emitters or hot air. The SRS module is a fully automatic ring production device that is used to produce specific solder rings from customer and product-specific solder wires, with or without flux core. Depending on the tool used, different solder wires with defined ring diameters can be produced. The automatically reproducible solder rings can be positioned manually, with the help of special tweezers and magazine dispensers, as well as automatically by means of a special, highly dynamic pick & place handling system on the solder joints to be processed or over the plated-through pins.

Solder rings in size comparison

Added customer value

- Highly accurate soldering processes due to reproducible solder quantities

- Sustainable, as almost 100% of the solder wire is processed

- No inert gas atmosphere (nitrogen) required

- Low space requirement compact design, freely integrable and modularly expandable

- Cycle time optimised (I) due to the elimination of pre-heating times and immediate availability

- Cycle time optimised (II) by decoupling the assembly and soldering process

- ➞ Cost-reducing because energy-saving, minimum service effort and cycle time-optimised

EUTECT SRS process steps

Wire feeds

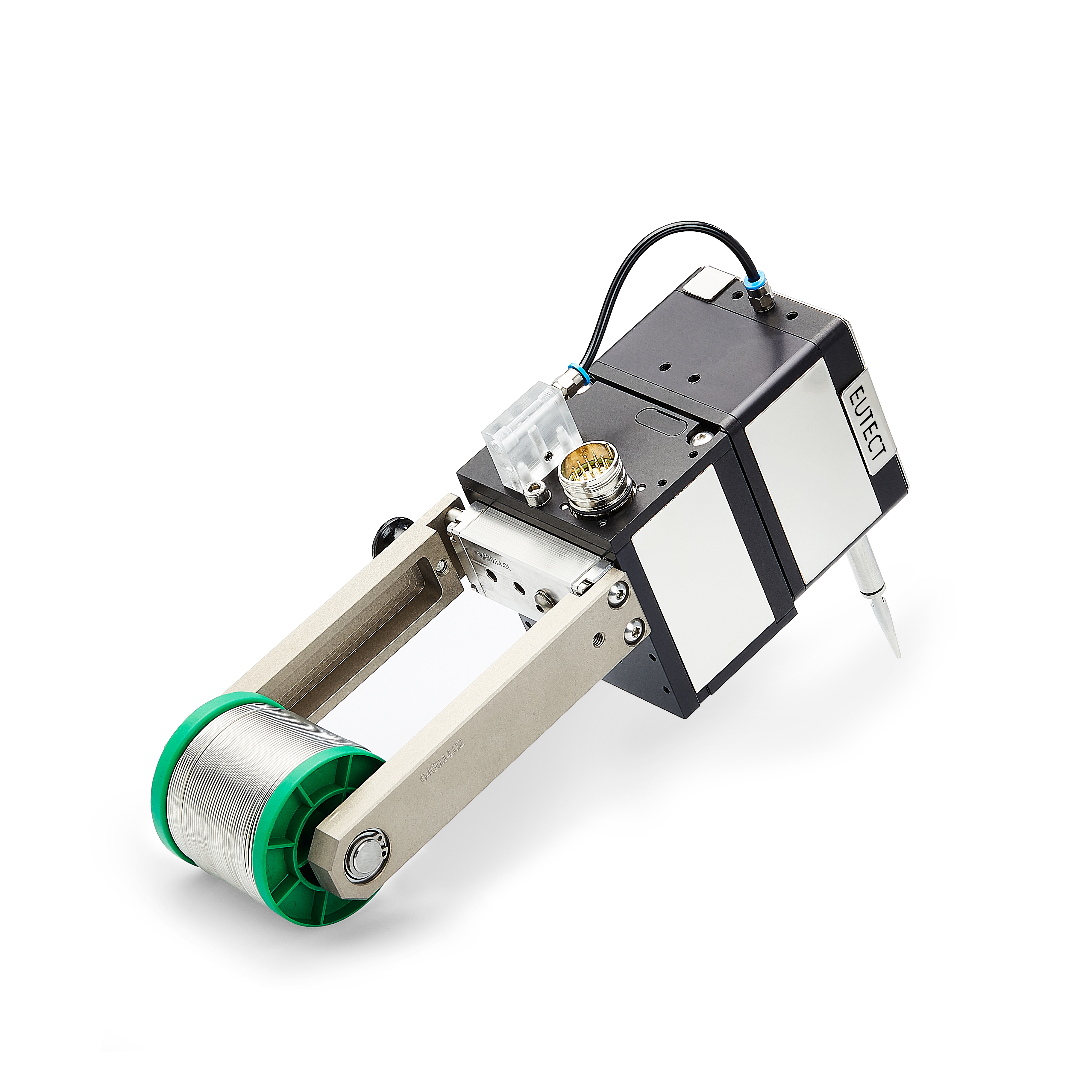

Besides non-regulated wire feeders for diverse wire thicknesses, EUTECT also offers the only force-controlled wire feeder in the world: the Sensitive Wire Feeder (SWF).

Sensitive Wire Feeder (SWF)

- High reproducibility

- Scope of application for laser-, induction– or piston soldering and build-up welding

- Sensitive and fast regulation of the feed force

- Minimal maintenance- and service work

- Flexible integration options

- Compact control unit EcoGerD

- Only force-controlled wire feeder in the world

- Speed up to 200mm/sec.

- Easy adaptation to different wire thicknesses (0.1-2.0 mm)

- Integrated inclination sensors (optional)

- Visualisation of all parameters

- 100% traceability

- Can be freely parameterised

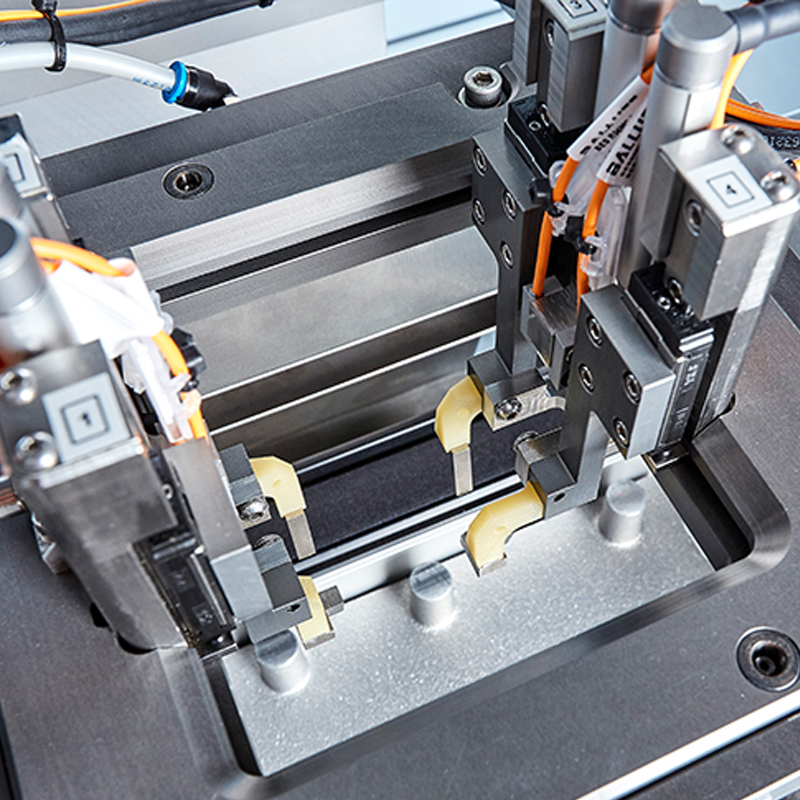

Workpiece carrier & Mask technology

For transport and protection of assemblies within the plant, workpiece carriers (WC) and soldering masks are used. These are developed individually for the assembly to be processed.

Workpiece carrier (WC)

- Satellite workpiece carriers

- Highly flexible function WCs

- Weight-reduced WCs

- Application of smaller robots

- Reduced footprint of the machine cell

- Considerable cost reduction

- Reduced maintenance work

- Integrated hold-down function

- Assembly-specific WCs

- Easy WC-change

- Integrated placement inspections (optional)

Mask technology

- Optimal cycle time

- Maximum service life

- Reduced maintenance work

- Reduced cleaning work

- Maximum solder joint quality

- Maximum component protection against heat and flux

- Pressure mask technology

- Integrated component placement support

- Exact component positioning

- Integrated inquiry intelligence

- Maximising of the process window

- Integrated heating function

- Miniaturisation and functionality with titanium inserts

Fluxing

- Freely integrable and expandable flux modules

- Highly precise inject fluxing

- Splash-free brush fluxing

- Area efficient spray fluxing

- Cycle-time optimised lift/dip fluxing

- Lasting flux treatment

- Reproducible flux monitoring

- Quantity- and position-monitored inject fluxing

Preheating / Cooling

- Freely integrable and expandable preheating and cooling modules

- Exact temperature processes due to tunnel systems

- Pyrometer-controlled heat input

- Homogeneous heat input due to blower heating

- Highly dynamic heat input due to quartz radiators and IR heaters

- Heat-protection masks for sensitive assembly areas

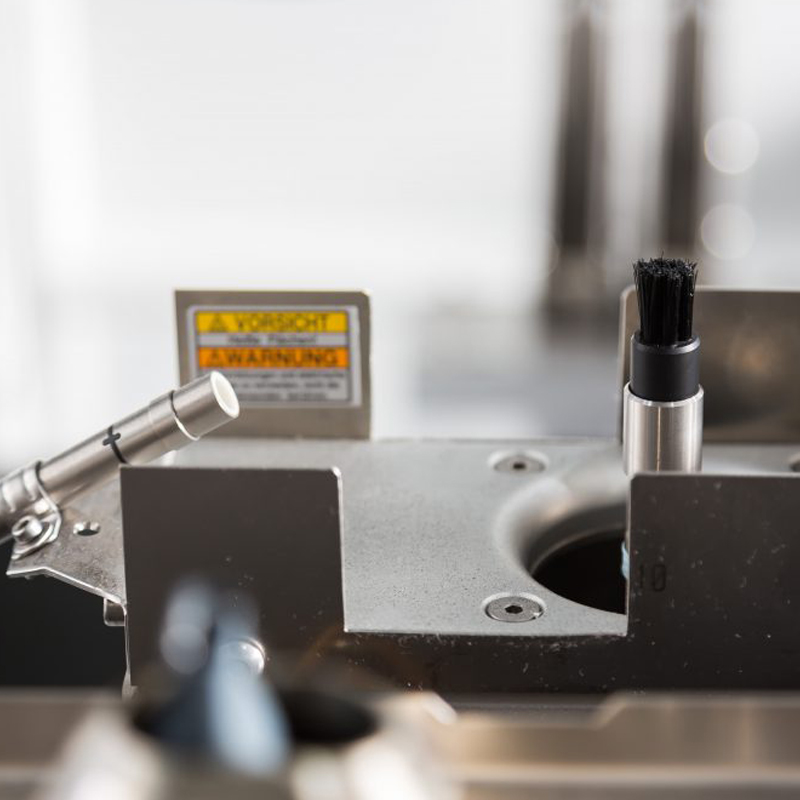

Brushes

- Cleaning of circuit boards

- Low maintenance

- Fast exchange of brush heads

- Durable, stable brush rotation

- Wearing part monitoring

- Integrated extraction

- No static charging

- Speed coordination to circuit board and components

- Defined brush height to circuit board

- Integrated height monitoring

- Round brush

- Fastening with thread

- DC-Motor with fixed speed

- Catch container for dirt particles

- Integrated ionising unit with discharge head

Inspection

- Ensuring maximum quality demands

- Fault-free quality control

- Cost-reduced monitoring

- Constant process speed

- Constant footprint

- Integrated solder joint inspection

- Fully automatic inspection process

- Integration of AOI systems

- Manufacturer-independent

The EUTECT factor

Many pieces of the puzzle make the EUTECT soldering processes efficient and reliable.

This includes parameters such as minimized production costs, as well as low cycle times and downtimes.

To achieve this, we invest a lot of time in the development of our modules. We take our customers’ suggestions for optimization and incorporate them into the further development of each individual module. This results in constant further development of all EUTECT products.

Using the IW1 and IW1-2 mini-waves, we illustrate what this means in individual cases.

The EUTECT factor