The MPC platform is a highly flexible automation solution for a wide range of tasks using a collaborative robot system from Mitsubishi Electric. The standard system is equipped with a light grid protected input and a rotary table for assembly input.

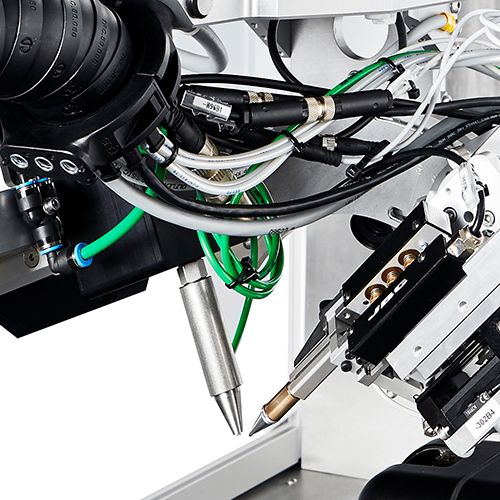

The MPC can be equipped with various tools. In addition to piston soldering heads, dispensers, screw or placement tools and grippers are also being considered for integration into the MPC. Depending on customer requirements, the MPC can be equipped with different tools for different applications. It is also possible to use a wide variety of tools in one work process.

The robot used is a MELFA assista from Mitsubishi Electrics equipped with the latest MR-J5 servo motors in all six axes, which eliminate the need for additional torque sensors.

Not only because of its high rigidity and industrial design, it can set solder dots with the same repeatability as a standard robot, but also because the MELFA assista can also be operated as an industrial robot.

MPC KL

The complete system MPC KL (piston soldering) can be equipped with piston soldering systems from JBC or HAKKO. The soldering iron sits firmly mounted on the arm of the robot, including the wire feed. Robots, control systems and soldering irons are a machine unit. The entire system is completed by the input area, which in the standard version consists of a rotary table for manual component assembly and a safety cell around the soldering process. Furthermore, a soldering tip holder is provided in the process surface itself, with which the fully automatic change of the soldering tips takes place. The same applies to the tip cleaning.