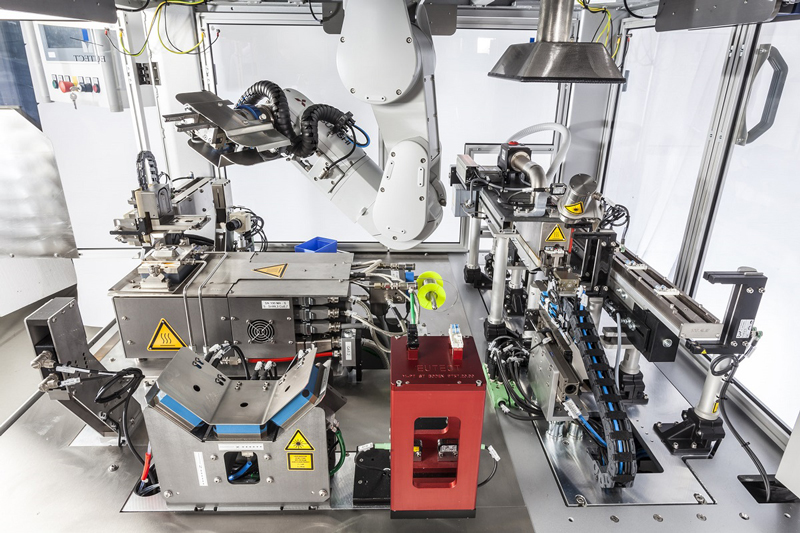

EUTECT-Kinematics

In the framework of an evaluation, the right kinematics modules are selected for the customer. The assemblies, possible workpiece carriers, cycle times, production volumes and the soldering modules used thereby play a part.

Different combinations of cells, handling- and process modules are possible according to the task. From this variety of combinations, individual solutions beyond the standard can be implemented, that are oriented to the customer requirements in every detail.