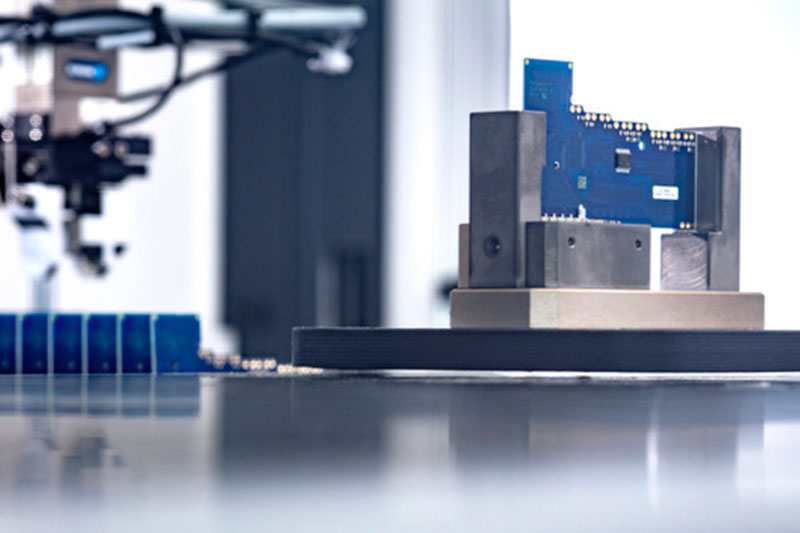

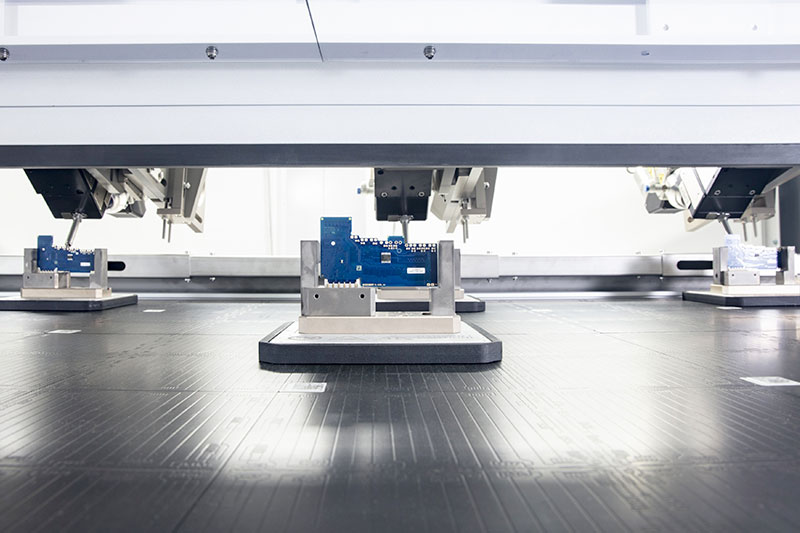

The use of the XPlanar from Beckhoff is characterised by maximum flexibility, dynamics and sustainability.

EUTECT Modular System

XPlanar

The floating 2D product transport combines the advantages of conventional transport and kinematic systems and supplements them with maglev technology. This creates new options for product handling.

In inline production, this results in design scope that cannot be achieved with conventional belt transport systems. At the same time, the positioning of a product during processing becomes the task of the transport system for the first time.

The movers transport the assemblies intelligently and with optimised cycle times from process station to process station. This massively increases the output and efficiency of the machines used for series production.

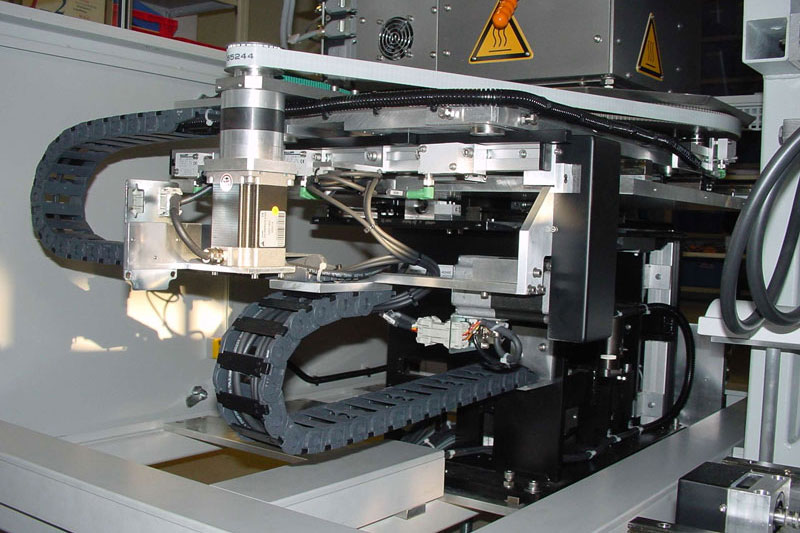

Z-X-Y-D lifting module

In addition to the travel range in X, Y and Z, a module, such as a soldering module, can rotate on the lifting table.

Although the angle of rotation is not completely 180° due to the connections of the soldering module, extended flexibility can be offered due to the rotation options.

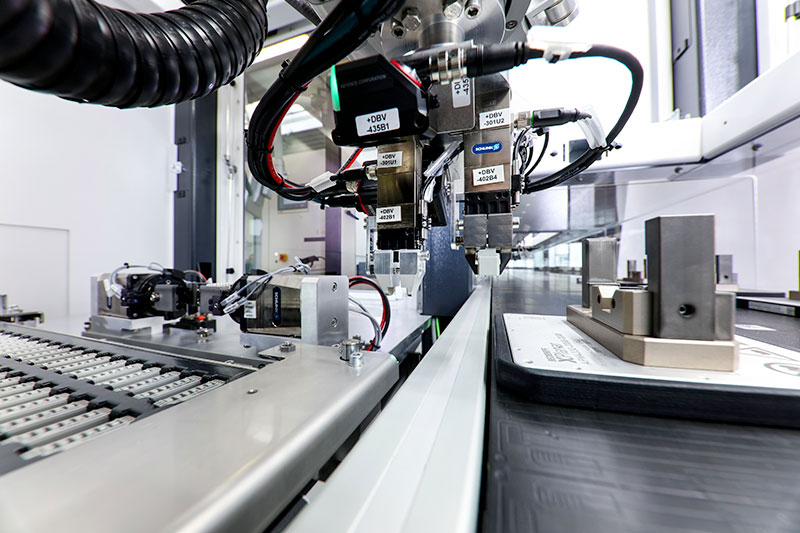

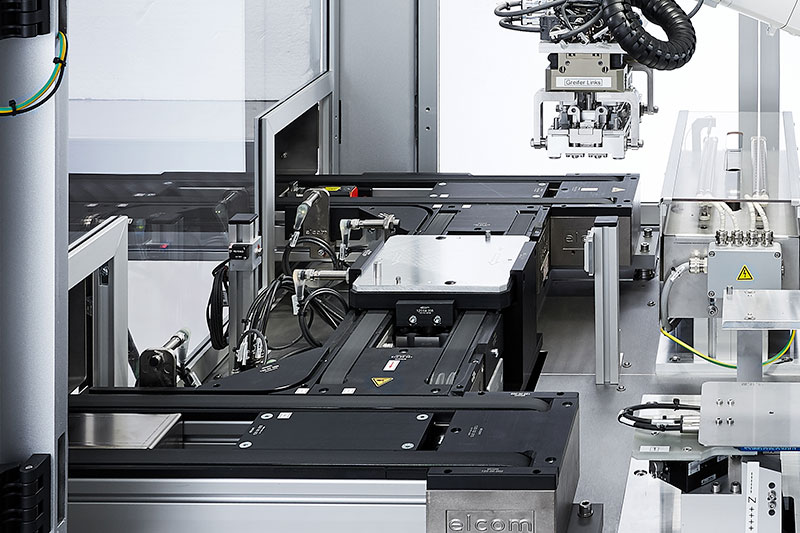

In-line conveyor system

With the in-line conveyor system, assemblies or workpiece carriers can be transported through the process cell.

Robots, for example, can then pick up assemblies from the transport system and move them to the respective process modules. The transport conveyor systems are designed for the respective widths and weights of the assemblies.

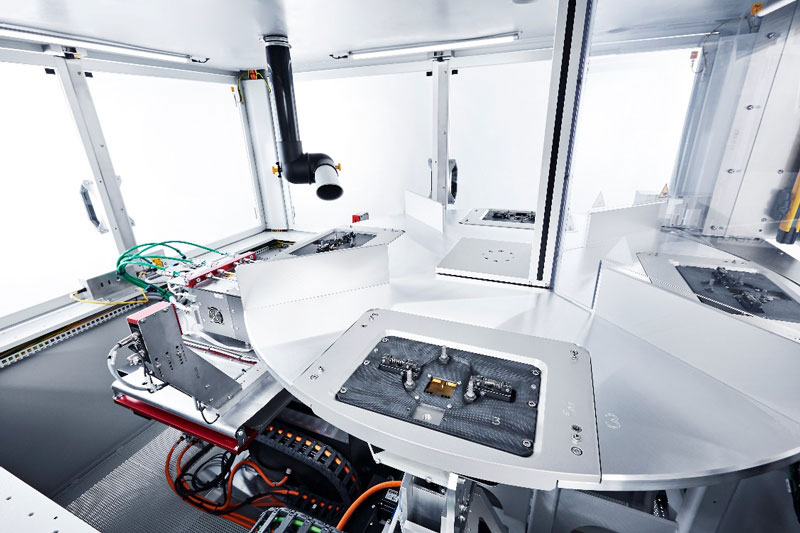

Rotary indexing table

The rotary indexing table enables simultaneous process machining with simultaneous assembly transport.

This increases cycle times and minimises errors thanks to simple, manual placement. The use of this kinematics is process-independent and can be individually adapted to assemblies and workpiece carriers.

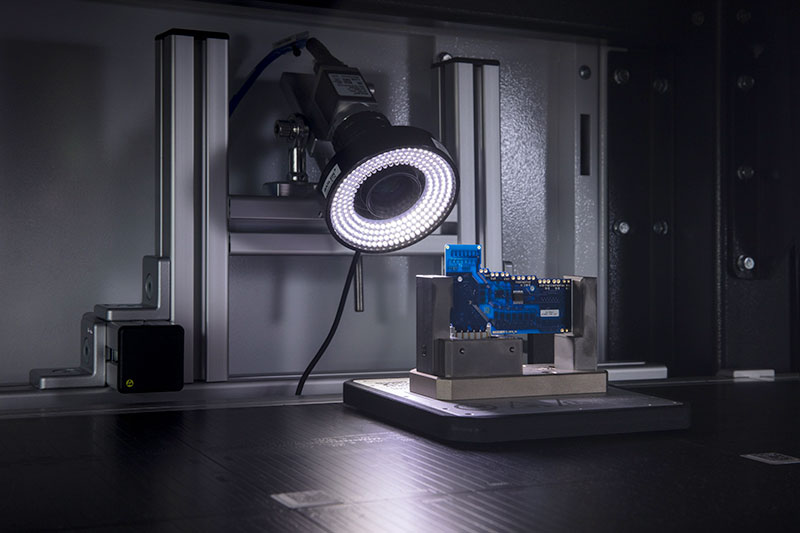

X-Y-Z axis system

With the X-Y-Z axis system, all positions on the assembly can be approached in two-dimensional space.

The travel range can be defined individually. Depending on the application, the Z-axis can be equipped with a universal carrier, a wire feeder and the corresponding laser, soldering iron or induction head or even thermode or laser knife modules.

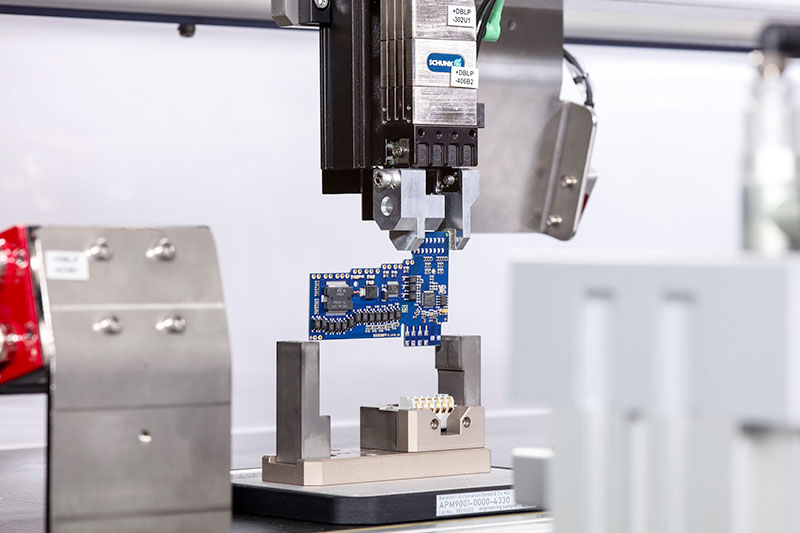

Robots

Up to two 6-axis robots can be integrated in a production cell on the floor or overhead.

This makes it possible to implement versatile, fully automatic process options, save on workpiece carriers and belt systems, and optimise cycle times in the smallest possible footprint.

Eutect mini-wave with robot – Mitsubishi

Eutect mini wave with robot – Stäubli