Product of the month july: Thermode soldering module

The EUTECT thermode soldering process enables the processing of flexible foils, cable strands and flat ribbon cables as well as specific SMD components. A high result quality and reproducibility is achieved in the soldering process. Thanks to low set-up times, the thermode soldering process is characterised by high cycle time optimisation. Low solder consumption, high energy efficiency and low maintenance requirements enable very efficient soldering.

The energy input is freely definable. Due to the temperature-force-path control, all process parameters are controlled and stored for complete traceability, such as the sink-in path control in 1µm steps, contact pressure from 1-60 N or the contact force, which is displayed in 0.5 N steps. Force, set travel and temperature are controlled, visualised and recorded via an HMI control unit. This gives the overall process performance the best possible availability and traceability.

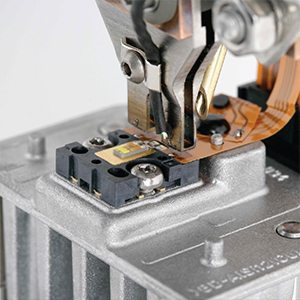

The thermode ensures that heat is applied quickly and precisely. Integrated cooling is also possible. Pre- and post-hold-downs fix the components to be soldered and guarantee an exact soldering result.

The modular EUTECT thermode soldering systems can be used as stand-alone or integrated into inline processes. The application-specific thermode geometries are protected by an automatic capton feed and keep the soldering process stable.