Product of the Month January 2024: Flux Application

Fluxes are an essential component of a soldering process. Flux application, as an individual process, therefore requires just as much expertise as the subsequent soldering process. This is why EUTECT offers various processes to provide customers with the right solution for flux application: from high-precision inject fluxing, spray-free brush fluxing and efficient spray fluxing to cycle time-optimizing lift-dip fluxing.

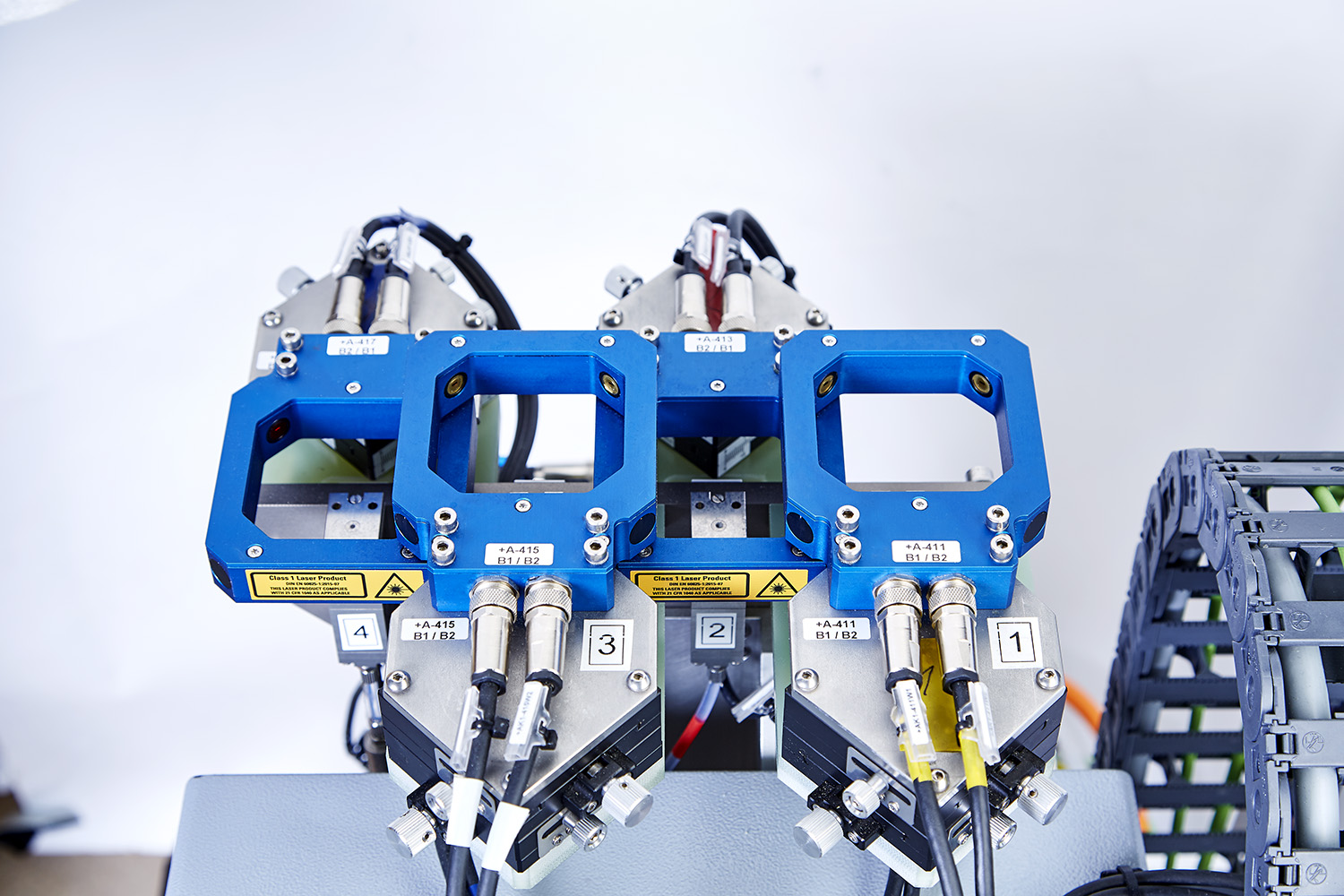

All process modules can be flexibly integrated and expanded within the Eutect configuration options, enabling sustainable flux application. In most cases, quantity and position-monitored inject fluxing is used, as it applies the flux with high precision to the defined areas and thus contributes to reduced flux consumption. Lift-dip fluxing is also frequently used. In this process, the surface to be wetted is dipped into the flux. Economical and sustainable flux handling is guaranteed with a two-chamber flux preparation system that ensures the perfect mixing ratio of the flux and also a cover that protects against evaporation. In addition, all spray jet application processes can be documented by means of flux jet monitoring, which ensures complete application monitoring.