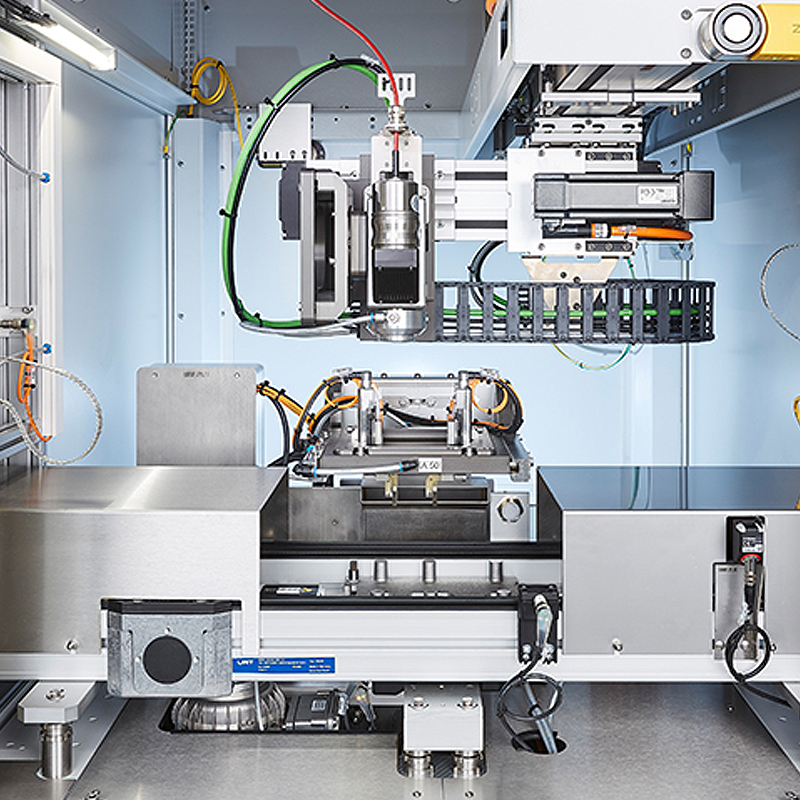

- Dynamic/cycle-time optimised soldering process

- Maximum process stability

- Maximum energy- and resource efficiency

- Can be used independently

- High process speed

- Short setup times

- Minimal solder consumption

- Minimal service- and maintenance work

- Low requirement for replacement- and wearing parts

- Minimum footprint

- 100% traceability

- Maximum process reliability

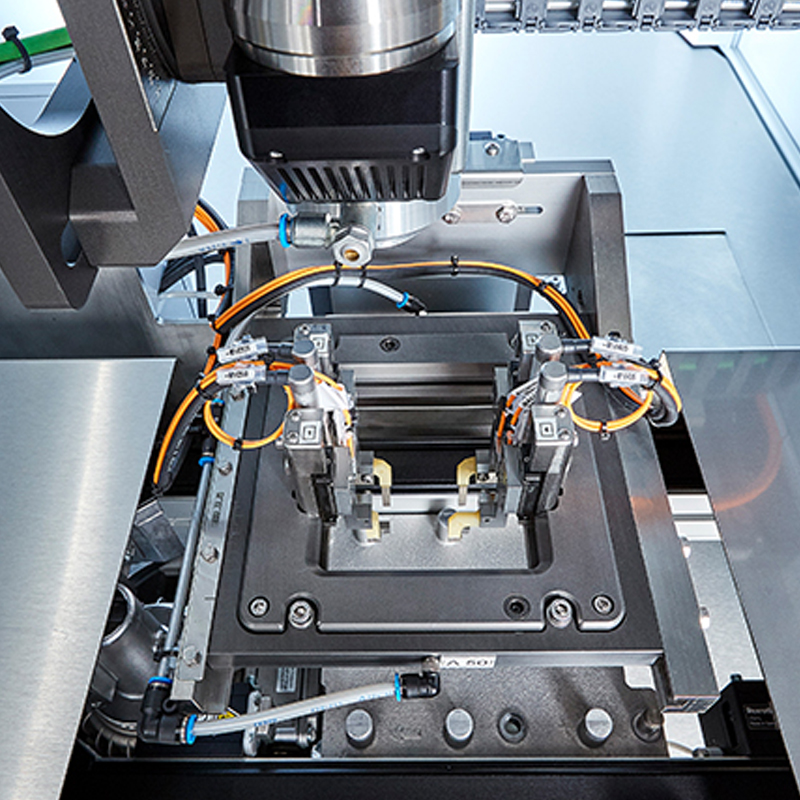

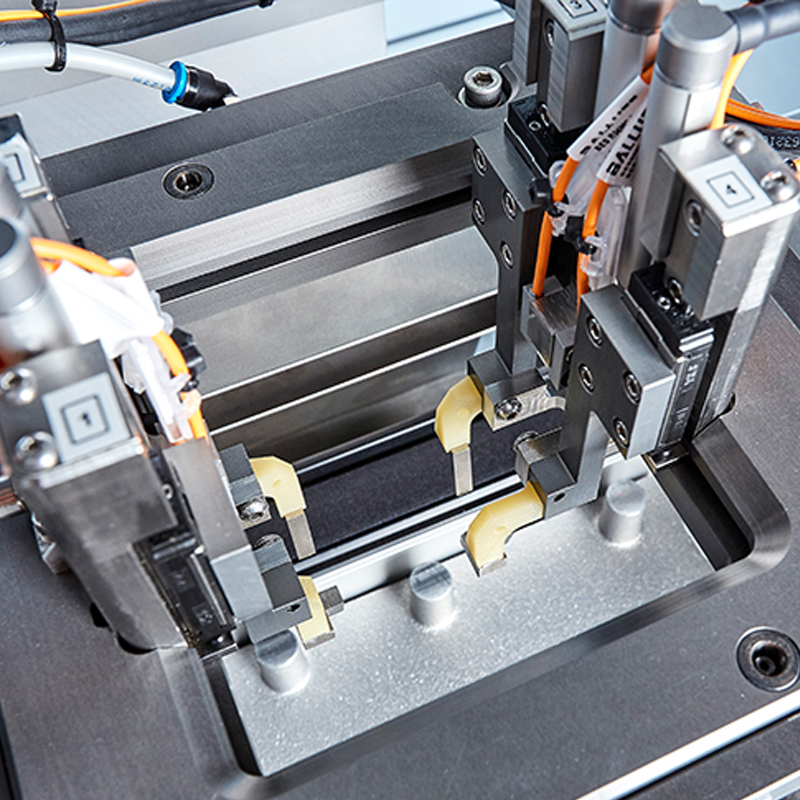

- Specific laser knife geometries

- µ-precise penetration

- Penetration control/-regulation 1µm

- Contact force can be regulated with 0.5 N

- Temperature-Force-Distance Control

- Fast heat input

- Fast, integrated cooling

- Redundant temperature measurement

- Maximum service life

- Freely definable energy input

- Immediate system- and process availability

Laser Knife machine integration