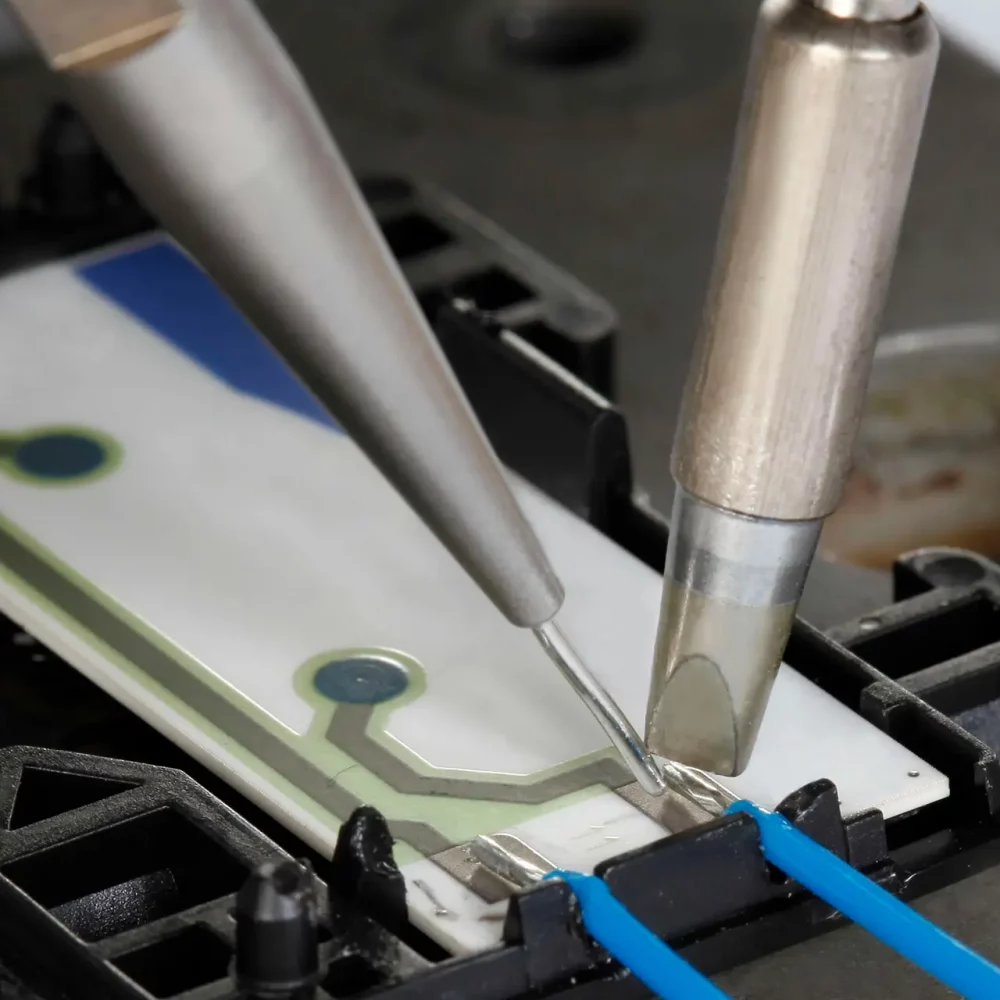

- Selective soldering

- Process technology

Our process technology is characterised by customised, efficient concepts made up of tried-and-tested modules.

Automation and kinematicsWe offer customised automation solutions that are precisely tailored to customer requirements.

- System integration

- Software

- Evaluation

- Service & maintenance

- Service, maintenance & training

Our service, maintenance and training services are customised to your individual needs.

Service contactSpare parts