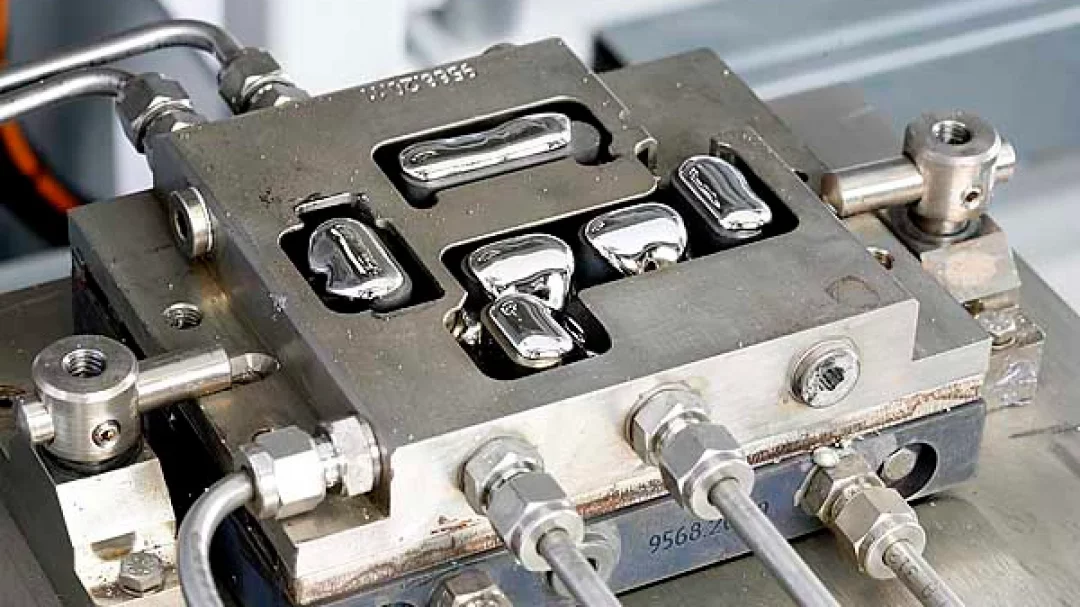

In mini wave soldering, the nozzle in combination with the titanium solder mask plays a central role in the process. In addition to workpiece carriers and masks, Eutect also develops soldering nozzles according to customer and process-specific requirements. The specialist for selective soldering combines maximum manufacturing precision with comprehensive material expertise.

„The nozzle shapes and stabilises the solder wave, allowing the liquid solder to hit the intended solder pads at a defined height and optimum flow speed. This targeted solder flow is crucial to ensure clean wetting and at the same time prevent unwanted solder spreading.“

Matthias Fehrenbach, CEO of EUTECT GmbH

The titanium solder mask completes this function by precisely defining the contact surfaces to be exposed and shielding sensitive components or conductor path structures. Furthermore, the solder flow is channelled and controlled with integrated baffle walls, pressure chambers and other geometric design elements. In combination, this creates a high-precision mini wave soldering process that delivers reliably reproducible results even with closely spaced soldering points. Eutect manufactures the solder masks according to customer specifications.

One of the main advantages of customised nozzles, masks and workpiece carriers lies in the high degree of customisability. As the shape, diameter and outlet geometry of the nozzle can be precisely matched to the opening structure of the titanium solder mask, it is also possible to process complex assemblies, for example with different component heights or varying thermal masses, without compromising on the soldering quality. The nozzle ensures an even supply of solder, reduces turbulence in the solder wave and thus stabilises the process. Thermal protection is also optimised by this combination. While the nozzle focusses the heat input spatially, the titanium solder mask acts as an additional thermal barrier. Neighbouring components are thus protected from unnecessary heat exposure, minimising material stress within the assembly.

Eutect therefore does not view the solder nozzle as an isolated element, but as an integral part of the entire soldering process. As the component is developed entirely in-house, a high degree of flexibility, precision and optimum harmonisation with the soldering systems, process modules and automation solutions can be guaranteed. The experience gained is continuously incorporated into the further development of the technology, supported by modern simulation and measurement technology.

I am your contact person!

Sales management