With miniwave or selective soldering only a small "solder current" or a very controlled solder wave is directed to specific soldering points, while neighbouring components and conductor paths are protected. To achieve this, solder masks are used to ensure that only the exposed pads are wetted and stray soldering, bridges or thermal damage to sensitive components are avoided.

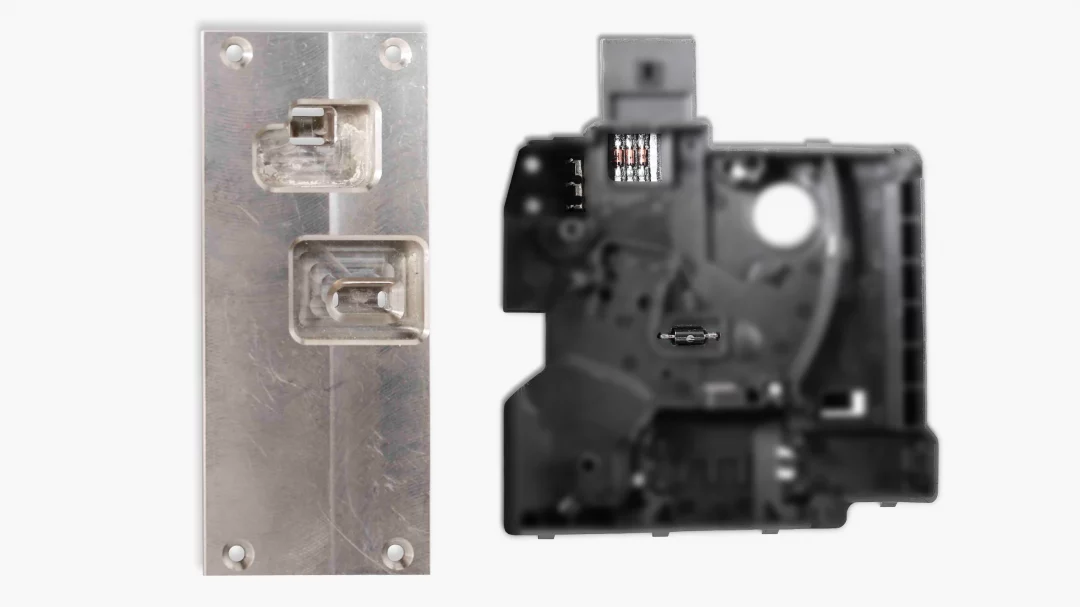

The titanium solder masks from EUTECT have special geometries, such as webs, chambers, baffle walls etc., which "guide" the solder, prevent unwanted wetting and are thermally stable. These titanium solder masks undergo a heat treatment to achieve a solder-repellent surface, which should lead to high reproducibility and minimised heat sinks.

This specific heat treatment of EUTECT is based on the following:

Change in surface structure / oxide formation

Thermal treatment can be used to influence the surface oxides or layers, e.g. to create a solder-repellent (non-wetting) surface or to reduce the adhesion of solder to titanium. The aim is to prevent solder from sticking to areas of the mask. The surface treatment positively changes the surface energy and roughness, which reduces the cleaning cycles and thus extends the service life of the mask.

Stress relief / relaxation

Titanium components can absorb internal residual stresses during production, e.g. through machining, laser cutting and forming. Such stresses can be reduced by targeted annealing or thermal post-treatment. This is important to ensure the dimensional stability of the fine structures over many thermal cycles.

Grain growth / microstructure optimisation

The microstructure of a metal (grain size, grain boundaries, recrystallisation) influences mechanical properties and thermal stability. Appropriate heat treatment controls this microstructure in order to minimise the formation of cracks or microcracks under thermal stress.

Heat-treated titanium solder masks make a decisive contribution to the quality stability and reproducibility of mini wave and selective soldering processes, especially for narrow, complex assemblies. The heat treatment optimises the mechanical, thermal and surface properties of the mask so that it functions as a precise, durable and reliable tool in the soldering process.

"I am your contact person"

Sales management