Coiltech - Meeting place for winding technology and power electronics

Coiltech is one of the leading trade fairs for coil and winding technology, electric motors, transformers and power electronics components. Developers, production managers and system integrators come here to find solutions for highly stressed assemblies, from electric drives and power modules to inductive components.

The focus is on materials, processes and automation concepts that reliably master high thermal, electrical and mechanical requirements. This is precisely where EUTECT's modern, selective soldering technology comes in: precise, reproducible and reliable, even with demanding geometries and temperature windows.

High-temperature & mini wave soldering from EUTECT: Precise soldering processes for demanding assemblies

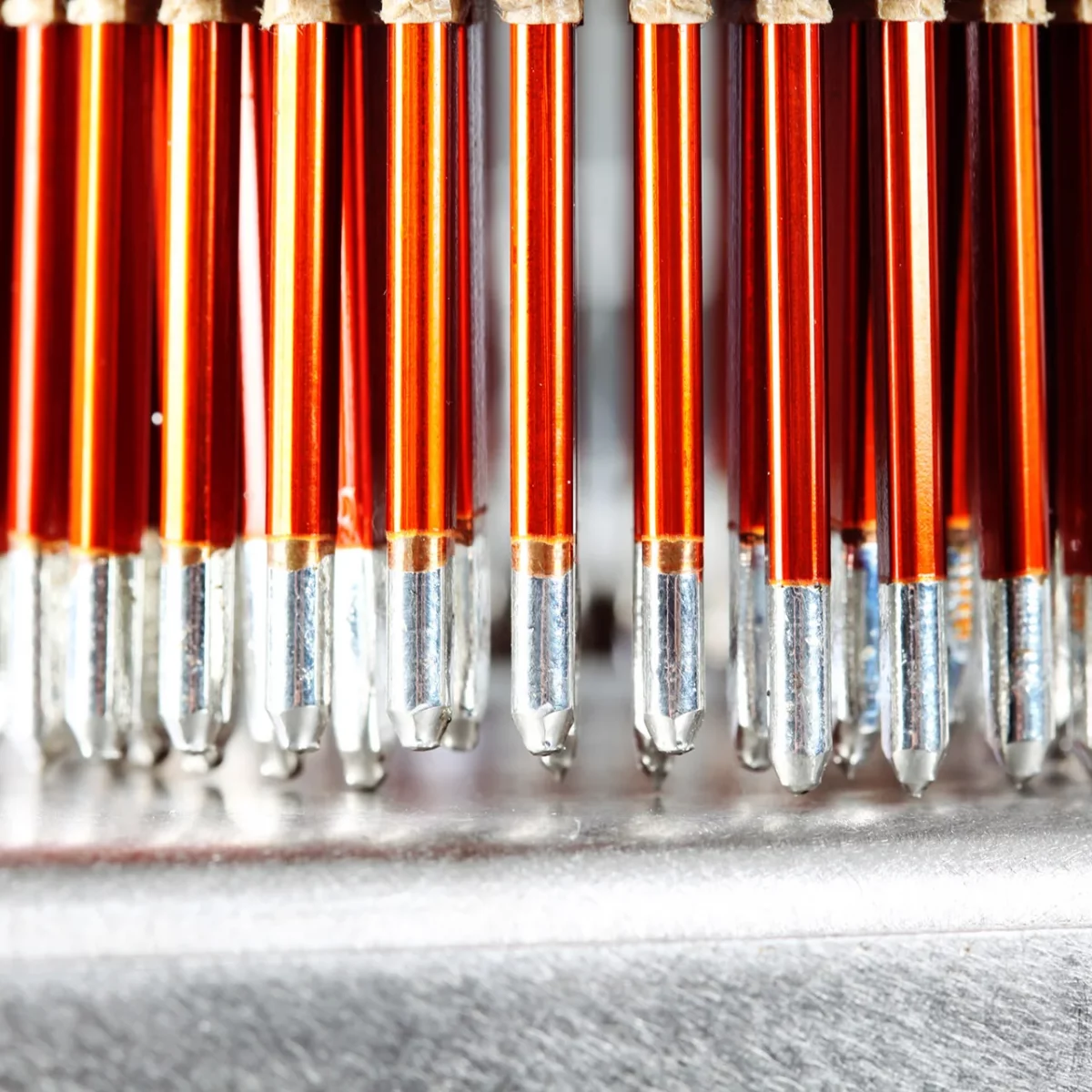

EUTECT addresses the requirements of Coiltech's target groups with specialised solutions in high-temperature and mini wave soldering. Particularly for coil connections, solid copper cross-sections, power semiconductors or thermally highly stressed contacts, mini wave soldering enables localised, controlled heat input as well as clean and reliable stripping of copper wires. This is ideal for temperature-sensitive environments while maintaining high soldering quality.

In-depth material and soldering process expertise from over 30 years of experience, which flows into the development of our high-temperature soldering modules, ensures stable and reliable connections, even under continuous load and high thermal stress. Thanks to modular automation concepts, the systems can be flexibly integrated into existing lines, from stand-alone processes to inline production. For users in motor, generator and power electronics production, this means reproducible quality, short cycle times and reliable processes, all tailored precisely to the challenges that are the focus of Coiltech.