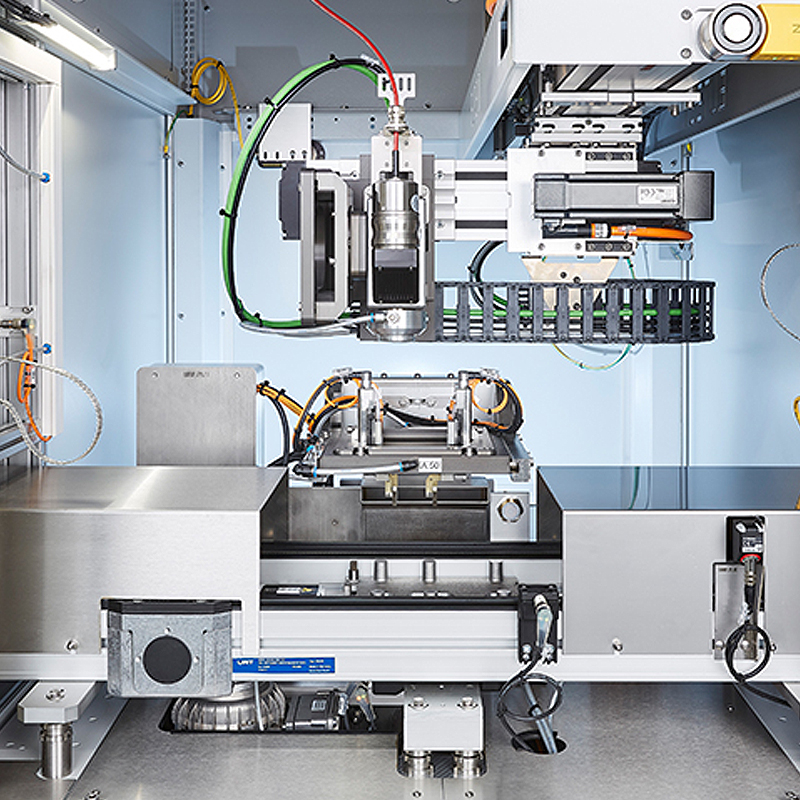

Zollner Elektronik AG relies on energy-efficient and cycle time-optimised alternative to thermode soldering

The Laser Knife developed by Eutect enables optimum results when soldering flex foils, cable strands, ribbon cables and battery pins.

Product of the month April: Laser Knife

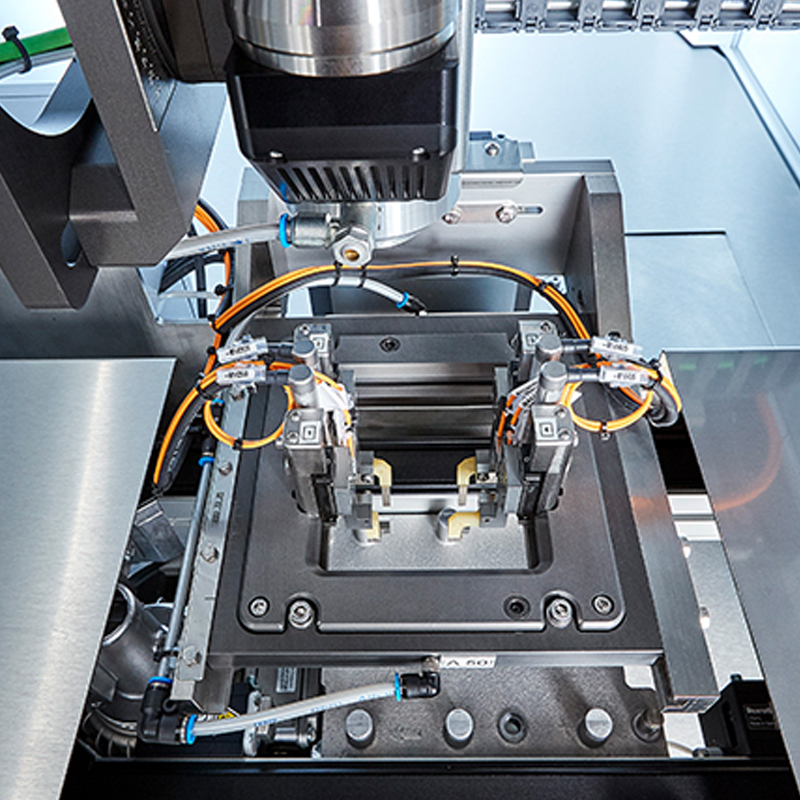

The Laser Knife consists of a displacement and force-controlled hold-down device that brings the two surfaces to be soldered together in a defined manner and a laser that enables the temperature to be applied without contact.