The EUTECT Miniwave Soldering technique follows the laws of physics and thereby ensures the most stable and efficient selective soldering process.

Use

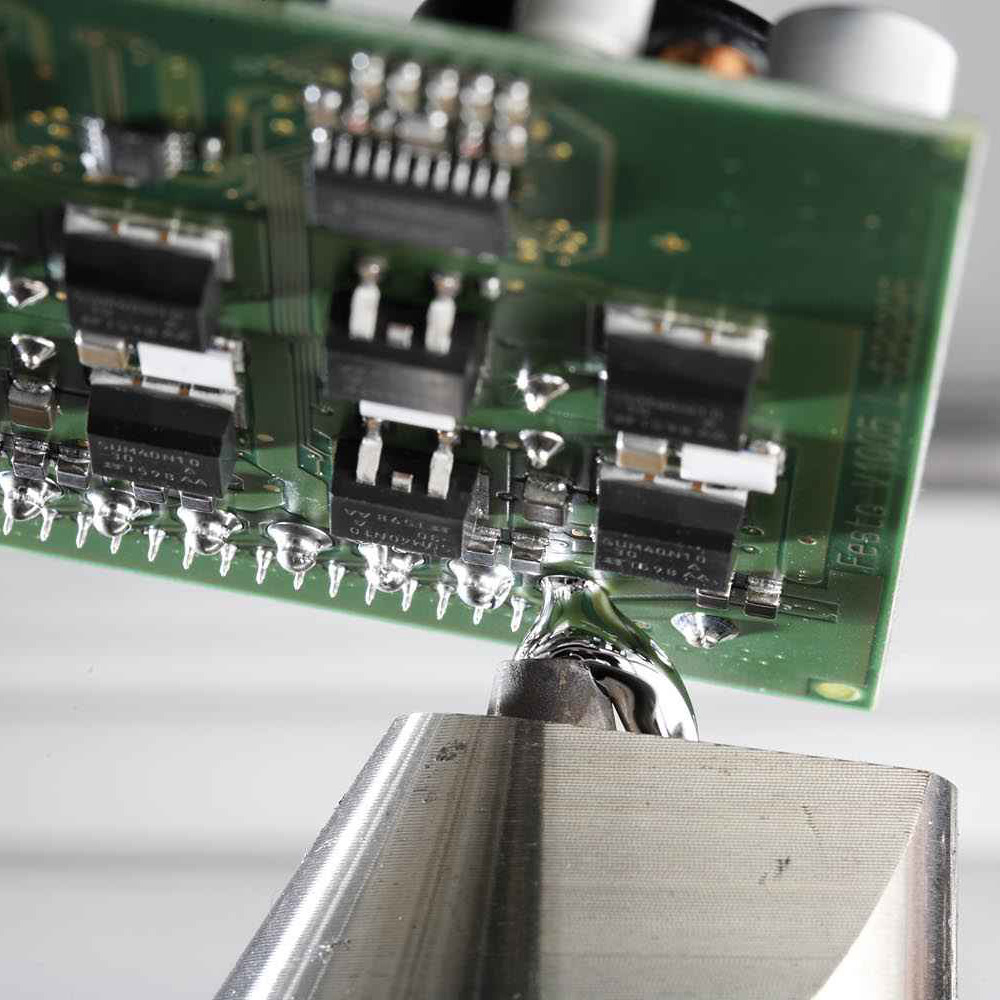

With the inert gas atmosphere, the selective solder wave guarantees a soldering process carried out free of oxides and residues. Due to the continuously pumped solder wave, the heat from the molten solder is transferred homogeneously all around to the solder joint geometry. The flowing solder wave thereby cleans the solder joint of surplus flux residues, oxides and contaminants.

Modularity

Together with the electromagnetic solder pump system and the quick-change soldering nozzles, the modular solder tanks of various sizes form the basic module of the process. The redundant temperature control, the constant solder bath level, the optional solder wave height control and the continuous solder wire tracking guarantee maximum system autonomy.

Performance

Due to the capillary filling level solder satiation, the solder joint is distinctly physically self-setting. The optimal solder geometry is thereby shown process-reliable by Pad-Pin form, Pin-Hole position and thermal mass distributions in the circuit board structure. Solder step-throughs, menisci and intermetallic phase characteristics reproducibly round off the overall performance.