The world’s only force-displacement controlled wire feeder SWF from EUTECT is a decisive key technological prerequisite for piston soldering, induction soldering and laser soldering in order to make the entire soldering process safe and reproducible.

EUTECT Modular System

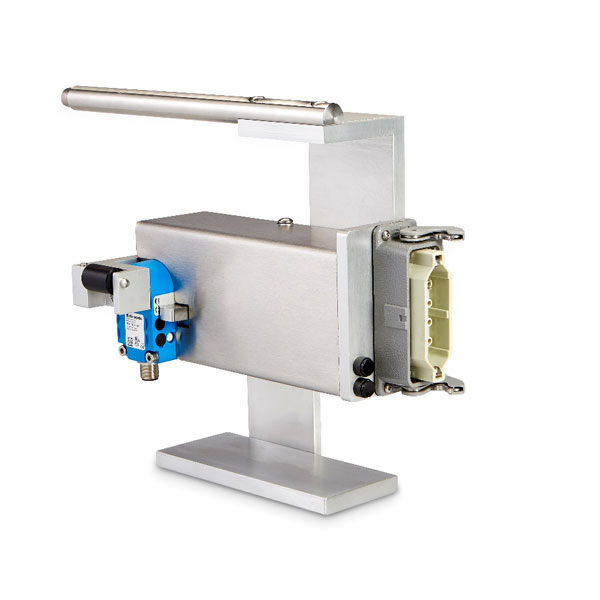

SWF (Sensitive Wire Feeder)

Thanks to the electromechanical sensor system, the SWF enables optimally controllable, reproducible and bend-free feeding of the wire and thus sets new standards in process reliability. The system detects the point in time at which the solder wire has reached the process surface and begins to melt by means of the change in the wire pressing force.

SWF-BW: build-up welding

The EUTECT SWF BW (SWF AS: Deposit Welding) module is used for controlled wire feeding with integrated gas flushing for build-up welding applications.

This achieves a higher level of reproducibility, quality and error detection in automated welding processes. The module enables wire feeding with a definable force. Thus, it is possible to react to different geometries and to apply the welding material in a defined height and density. Defects are also detected and the amount of wire fed is constantly recorded. Due to the variable connection and flexible interface design, the module can be integrated into existing systems with little effort. The wire feed can be adapted to specific geometries and the wire reel holder can be flexibly adjusted.

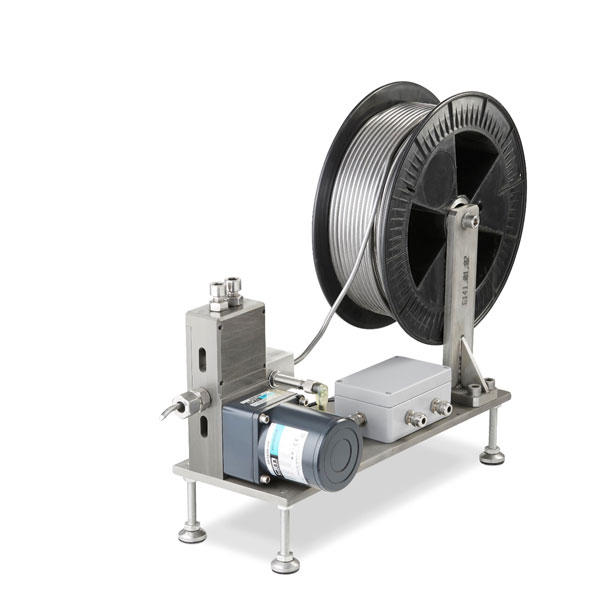

Wire feeder WF

The wire feeder WF is the unregulated version of the wire feeder SWF.

The WF is used when sensitive, fast control of the wire feed force is not necessary based on the application.

Wire feeder (1.5 – 6 mm)

EUTECT also offers unregulated wire feeders for different wire thicknesses of 1.5; 3.0 and 6.0 mm. These are used, among other things, for refilling the mini wave soldering modules.

The wire feeder transports solder wire into the solder tank to automatically keep the solder level constant. The presence of the wire is checked by means of an integrated wire sensor.