Solder mask inserts can be used to cover defined areas of the printed circuit boards for optimum and reproducible soldering results.

EUTECT Modular System

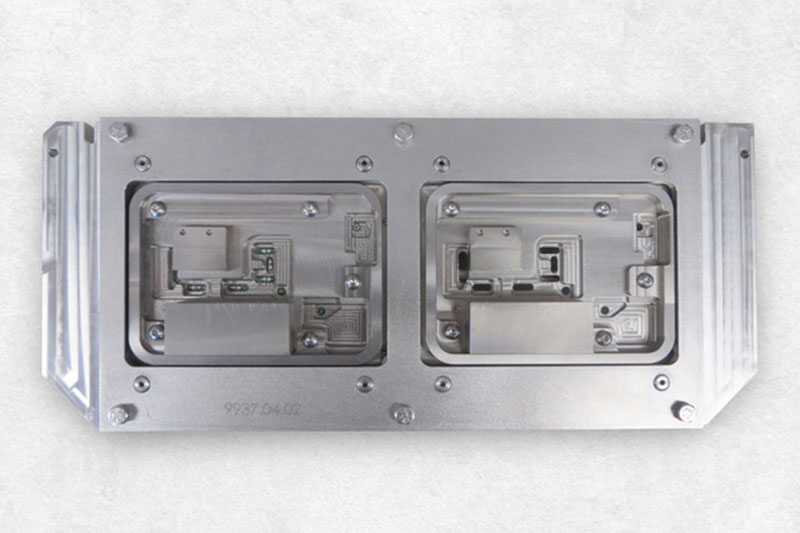

Solder mask insertion for workpiece carriers

They can be changed quickly and enable highly reproducible soldering results.

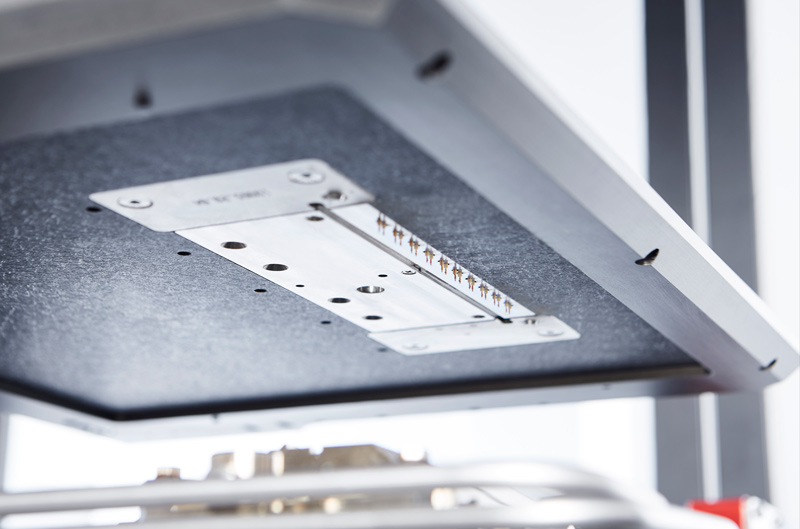

Solder mask insert for robot gripper

By means of solder mask insertion, areas of the PCBs can be covered for an optimal and reproducible soldering result.

They are quick-changeable, can be equipped with locks for further fixation and thus enable highly reproducible soldering results. The solder mask is recognised in the insert itself.

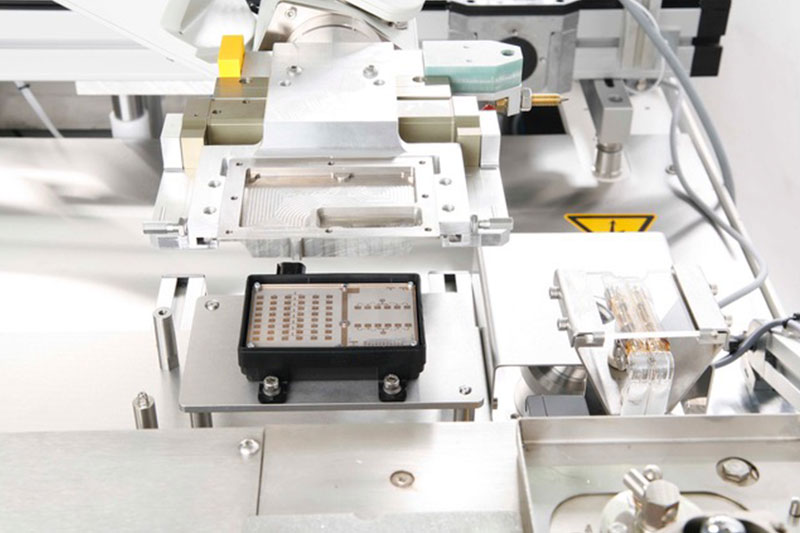

Spring-loaded titan mask

The customer only gets real process stability and benefits with selective soldering or soldering with mini wave and mask technology when the solder nozzle has been developed and manufactured in relation to the mask.

The increasingly complex assemblies, whether due to miniaturisation or difficult-to-access and sensitive geometries, demand new solutions in mask technology. For special, reliable solder nozzle-mask combinations, only the material titanium is commonly used. If, for example, PCBs are already mounted in housings and SMD components on the underside are very close to the housing and the THT solder joints to be soldered, the walls, intermediate webs and connections must be very thin. Nevertheless, the metal webs must be stable in the long term, which is why the masks are made of titanium.