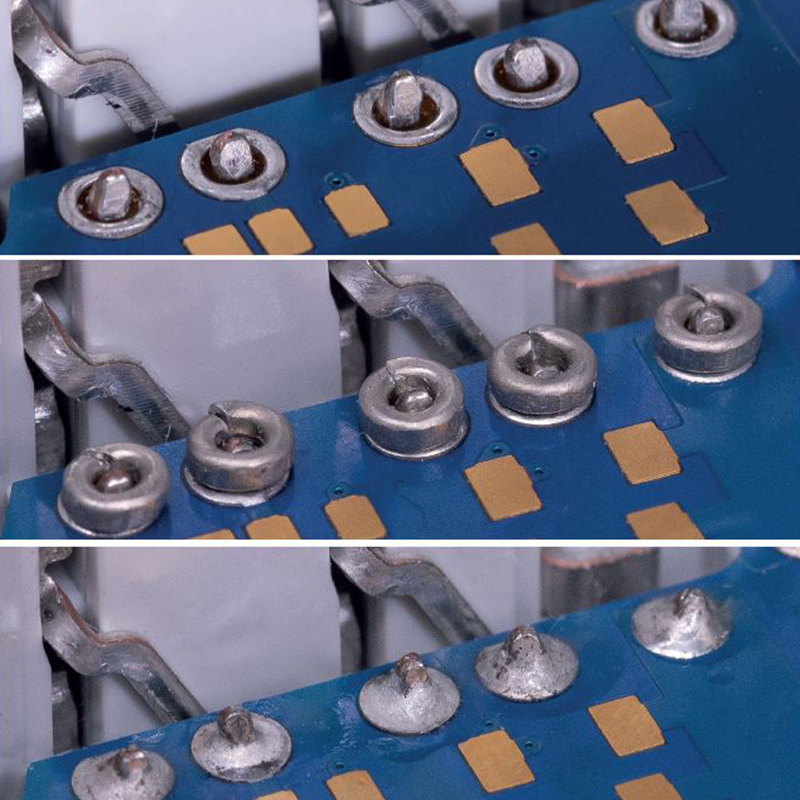

The Sustained Ring Soldering module produces solder rings from common solder wires, which enable a new cycle time-optimised, highly accurate and economically sustainable assembly soldering.Using the newly developed SRS module, pre-assembled solder rings can be produced on the fly and placed on and around THT pins. These are then processed by means of laser, piston or induction soldering processes, as well as by means of IR emitters or hot air. The SRS module is a fully automatic ring production device that is used to produce specific solder rings from customer and product-specific solder wires, with or without flux core. Depending on the tool used, different solder wires with defined ring diameters can be produced. The automatically reproducible solder rings can be positioned manually, with the help of special tweezers and magazine dispensers, as well as automatically by means of a special, highly dynamic pick & place handling system on the solder joints to be processed or over the plated-through pins.

Solder rings in size comparison

Added customer value

- Highly accurate soldering processes due to reproducible solder quantities

- Sustainable, as almost 100% of the solder wire is processed

- No inert gas atmosphere (nitrogen) required

- Low space requirement compact design, freely integrable and modularly expandable

- Cycle time optimised (I) due to the elimination of pre-heating times and immediate availability

- Cycle time optimised (II) by decoupling the assembly and soldering process

- ➞ Cost-reducing because energy-saving, minimum service effort and cycle time-optimised