EUTECT – innovation in action

Made in Germany

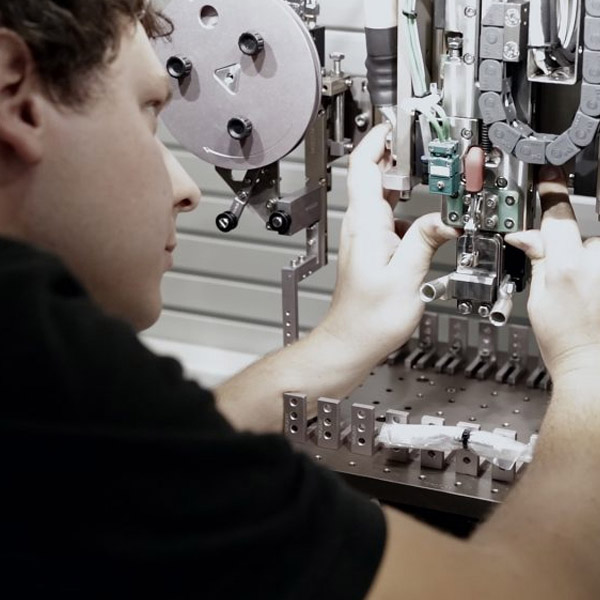

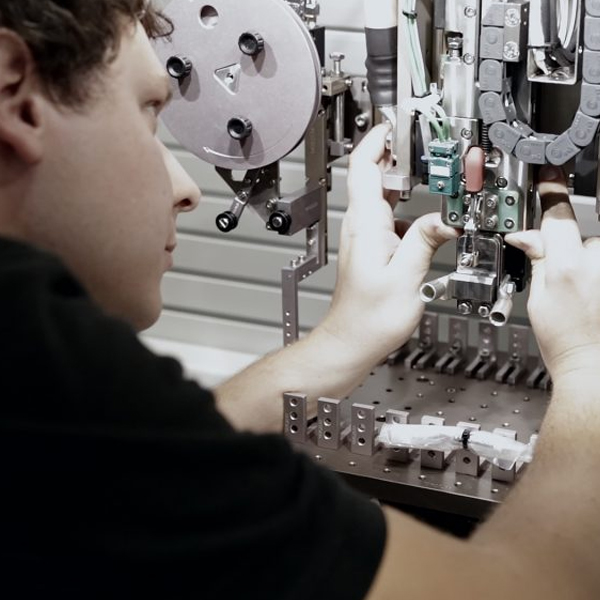

Our aim is to realise high-quality and technically perfect machines. It is all about the optimal solution for every customer.

EUTECT stands for a consistently applied quality management, that does not first begin during production, rather already during the development.

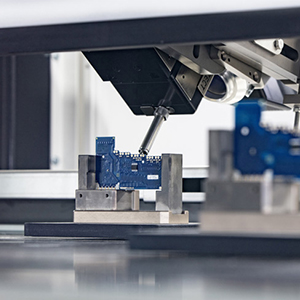

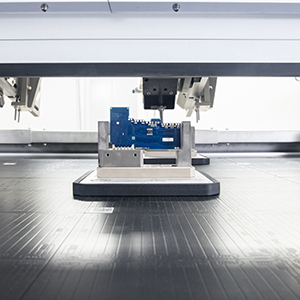

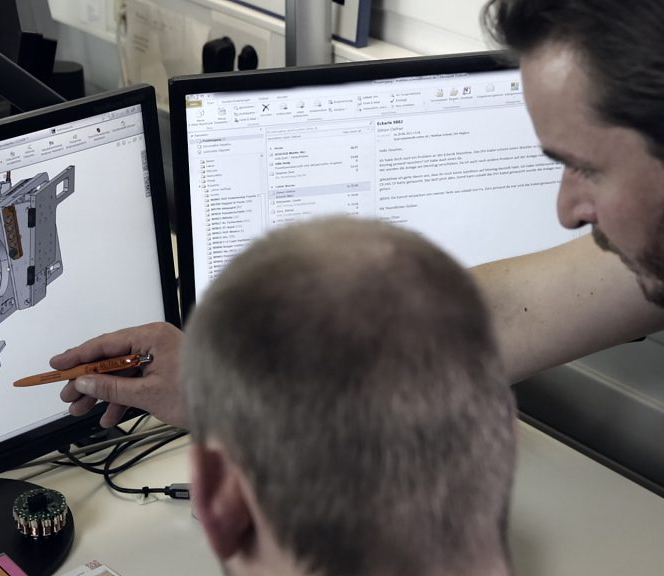

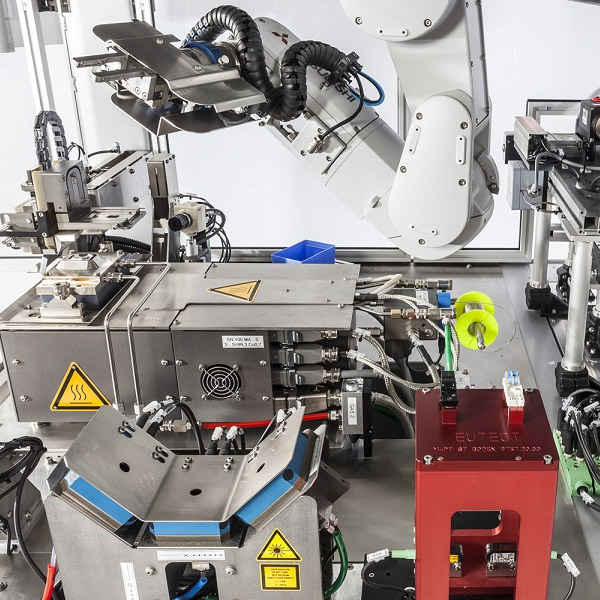

Contrary to the usual trend, we prefer a high real net output ratio. In our Technology Centre we find the optimal connecting process for your product. Modules and systems are developed in our 3D design system. We assemble, document and program in-house.

The commissioning takes place on our premises or on-site at our customers. In addition, by means of machine- and process training courses as well as production support, we offer our customers deadline security in the project and fast, competent support from a single source.

Consequently we guarantee products and services, that always and comprehensively meet the requirements for the seal of approval “”Made in Germany”.

Securing the future through sustained action

Every year we invest over 10% of our turnover in research and development. Our employees, partners and customers thereby ensure again and again for new, creative approaches.

Consequently EUTECT is always at the cutting edge.

We also promote this through the continuous further education of our employees. Internally, know-how presentations of the individual teams that are held every month ensure for the best possible transfer of knowledge in the entire EUTECT team. Through cross-team project communication, we create a great wealth of experience, from which every single employee profits.

We know: Every employee is part of the EUTECT problem-solving competence. An open, alert type of collaboration as well as a good working relationship in the team and with the customer is the foundation for lasting company success.

We are happy to share this company success, because sustained action does not end at the works gate. EUTECT supports a series of social and ecological projects nationwide and in our own region. Because as a part of society, it is a matter of concern to us, to act socially and conscientiously.

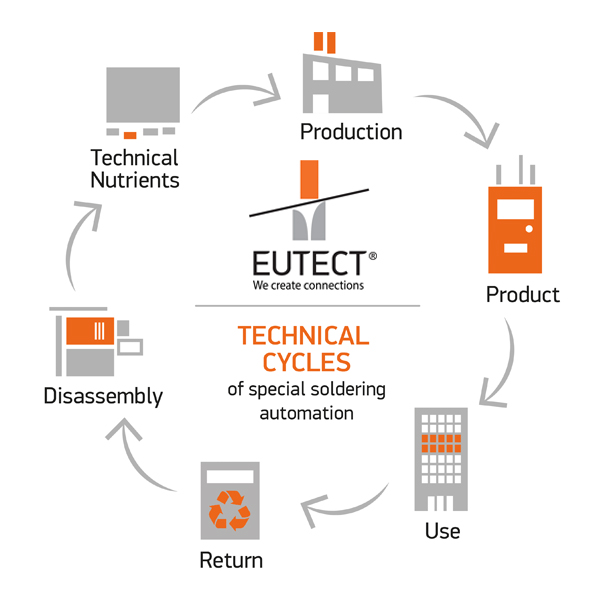

Cradle to Cradle concept

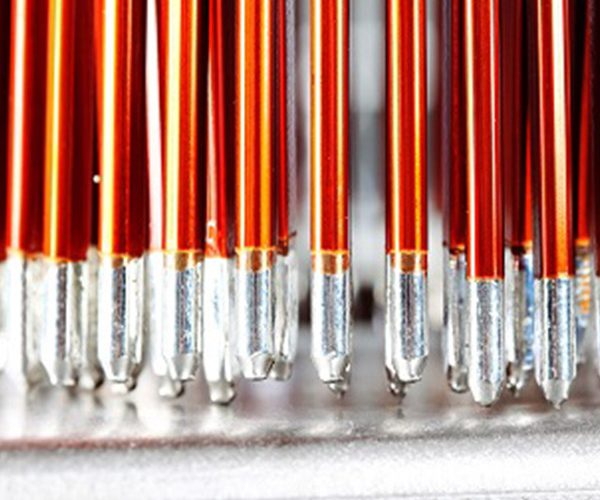

In every unit delivered by Eutect, not only labour time but also material values have been invested, which can be used for new projects. This can be, for example, the production cell, kinematic solutions but also soldering modules such as soldering nozzles, wire feeders or thermodes. If these parts are still operating, they can also be reused and can be integrated into other machine concepts if the sustainability and cradle-to-cradle idea is applied. This approach is based on a continuous and consistent recycling management. The German chemist Michael Braungart and the American architect William McDonough came up with this approach, which is based on “cradle-to-cradle products” that can be kept continuously in technical cycles as “technical nutrients”. Our “technical nutrients”, such as the production cell, soldering modules, robots or other kinematic systems are returned to our production after a thorough inspection and overhaul, as well as extensive functional testing, after this has been agreed to by the customer.

Customer loyalty through problem-solving competence

The customer and his problem are at the centre of our thoughts and actions.

For your products, your tasks and your specific requirements, we create solutions for mutual success. We thereby accompany and support you throughout the entire process of your product development. For the planned integrated circuit packaging (AVT), your products are jointly evaluated in a process environment suitable for volume production.

Our EUTECT Technology Centre is available for evaluations as well as pre-production soldering in order to find a practical solution under original process conditions.

All results and experiences flow directly into our product development. This know-how forms the foundation for the success of the project and the maximum technological benefit for further projects in the future.

We want to accompany you over the long-term.

We create connections

EUTECT cooperates with competent partners, such as universities, technical colleges, institutes, working groups, networks and ministries.

Through the professional exchange we want to secure and expand our top position in the market. Thanks to these networks, we can evaluate and analyse technical developments early, and if appropriate, integrate them in the technical further development of our products.

Downloads

Credentials

A career at EUTECT

Besides the support with final dissertations for Bachelor- and Master theses, EUTECT is also pleased to offer internships.

We place great value on being a long-term, dependable and social employer for our employees. By means of flat hierarchies and short decision-making routes, we make it possible for every employee to actively participate in the development of the company.

Trade fairs & events

Coiltech Deutschland 2024

20. – 21. March 2024

Augsburg, Germany

booth 2A-17

More information

Global Industrie 2024

25. – 28. March 2024

Paris, France

More information

PCIM Europe & SMTconnect 2024

11 – 13 June 2024

Nuremberg, Germany

More information